Easy to install/Corrosion-resistant/Long service life/High strength/High-efficiency filtration

Indicates the filtration accuracy of the filter element

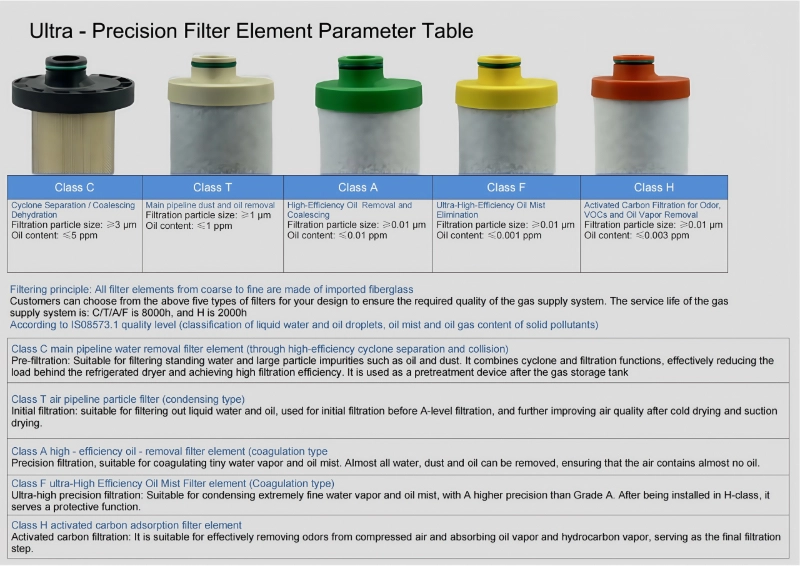

Class C:3 Micron (Pre filter)

Class T:1 Micron (After filter)

Class A:0.1 Micron (Line filter)

Class F:0.01 Micron (Fine filter)

Class H:0.01 Micron (Activated carbon filter)

YM Model | YM082072 | ||||

Original Filter Brand | ACF Series Precision filter | ||||

Original Model | YF-X-400 | ||||

Precision / Residual oil amount | 0.01 μm/0.01ppm | ||||

Processing capacity | 40.2 Nm³/min | ||||

Working Temperature/Pressure | 1.5~80℃/1.6Mpa | ||||

Shell material | Aluminum alloy | ||||

End Caps | Engineering plastic | ||||

Seal | Fluororubber | ||||

Connection size | G3” | ||||

| 12.8kg | ||||

Size packaging(cm) | 101*26.5*26.5# | ||||

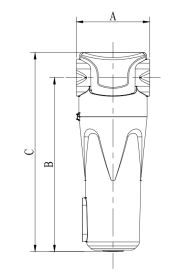

Dimensions(mm) | A | B | C | ||

210 | 800±2 | 875 | |||

Country of Origin / HTS Code | CHINA / 8421999090 | ||||

Notes | Please consult Yuanmei sales personnel for any remaining areas | ||||

Element Model | MS-400X | ||||

Origin | WuXi,Jiangsu | ||||

Transport Package | Carton | ||||

Key Advantages

YF-X-400 Aluminum Alloy Compressed Air Filter is engineered for demanding industrial air treatment systems. Designed with premium aluminum alloy and advanced separation technology, this filter ensures reliable removal of water, oil, and solid particles from compressed air lines. With a high flow capacity of 40.2Nm³/min and a maximum pressure rating of 16 bar, it offers a balance of efficiency, durability, and performance for continuous industrial use.

Core Features

* High Flow Rate: Handles up to 40.2Nm³/min, suitable for large-scale compressed air systems.

* Robust Build: Made of high-strength aluminum alloy, ensuring lightweight design with strong pressure resistance.

* High Pressure Tolerance: Operates effectively under 16 bar, meeting diverse industrial demands.

* Connection Size: Equipped with G3” port size for easy integration with standard pipelines.

* Filtration Precision: Effectively removes dust, oil aerosols, and moisture, ensuring clean and dry compressed air output.

* Low Pressure Drop: Optimized internal flow design minimizes energy loss and operating costs.

* Corrosion Resistance: Special surface treatment enhances durability and extends service life.

Diverse Applications

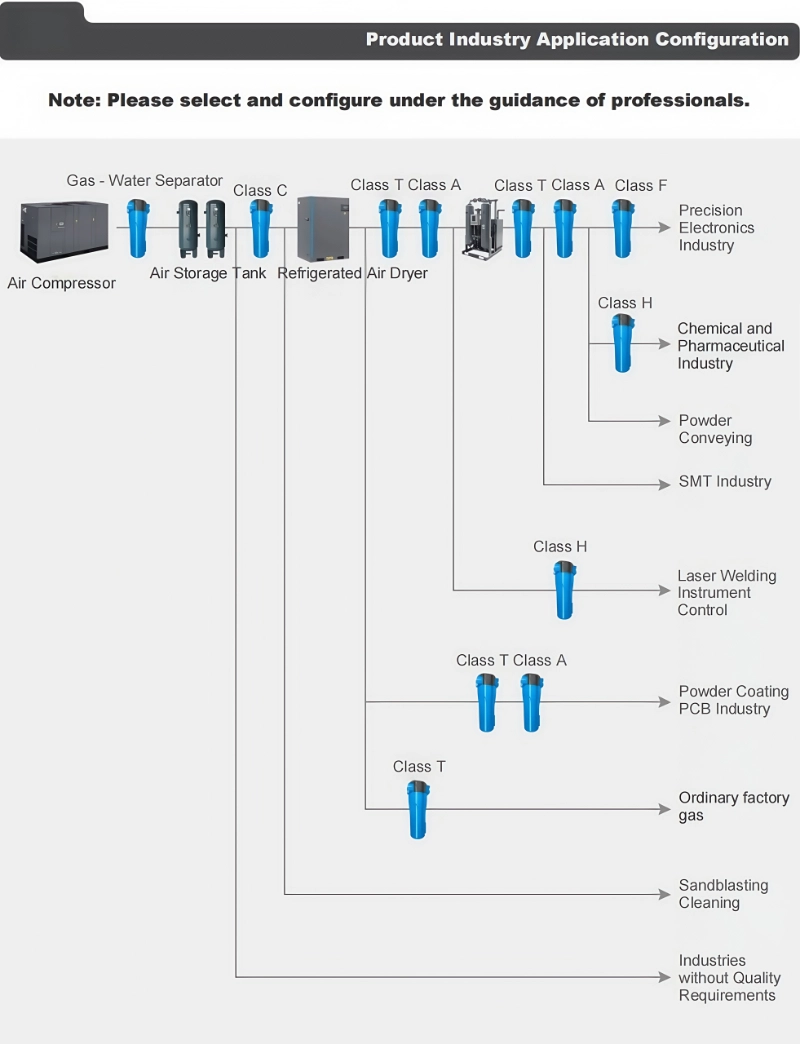

The YF-X-400 compressed air filter is versatile and can be applied across industries such as:

* Manufacturing: Ensures clean compressed air for pneumatic tools, assembly lines, and robotic systems.

* Automotive Industry: Provides contaminant-free air for spray painting, coating, and precision processes.

* Food & Beverage: Delivers hygienic air quality for packaging, bottling, and pneumatic conveying systems.

* Electronics & Semiconductors: Maintains ultra-clean compressed air for sensitive production environments.

* Pharmaceuticals: Protects sterile processes by removing oil and moisture contaminants.

* Energy & Petrochemical: Supports high-demand equipment with reliable filtration under harsh conditions.

User Value & Benefits

* Improved System Efficiency: Clean compressed air enhances machine performance and reduces downtime.

* Extended Equipment Life: Prevents damage caused by particles, oil, and water, reducing maintenance costs.

* Energy Savings: Low pressure drop translates to lower power consumption and operational cost savings.

* Consistent Air Quality: Stable filtration ensures better product quality in sensitive production lines.

* Long Service Life: Durable aluminum alloy structure withstands heavy-duty use with minimal wear.

* Cost-Effective Solution: Provides a balance of high performance, reliability, and reduced total cost of ownership.

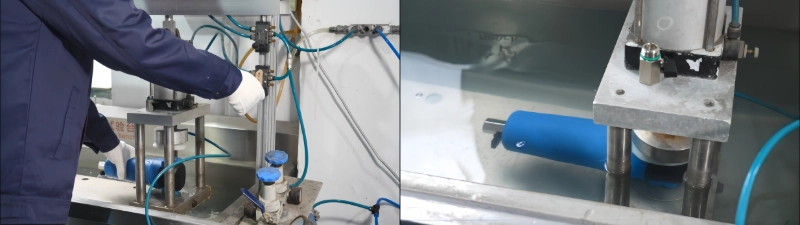

Testing Equipment:

The company has a dedicated testing laboratory and has introduced the German equipment-CS 0.1.

The testing requirements can meet the ISO-8573-1:2010 Class 1 standard

Air tightness test:

Before each filter leaves the factory, a 100% water pressure test for air leakage points must be conducted to ensure there is no energy leakage during use.

(Sampling for testing is strictly prohibited.)

Widely applicable:

Precision manufacturing: Laser cutting, precision electronics, and automated equipment

Surface treatment: Advanced spraying, sandblasting

Packaging and shaping: Bottle blowing

Life and health: Food and beverage, medical and pharmaceutical, clean laboratory

Industrial general: mechanical welding, mining, workshops, pneumatic tools, petrochemicals, etc

Through multi-industry application verification, this series of products can effectively enhance equipment operation efficiency, reduce failure rates, and extend maintenance cycles. It adopts a modular design, is easy to install, has low maintenance costs, and is compatible with equipment of various brands. The product has passed the ISO9001 quality system certification and complies with international standards such as CE and RoHS, providing customers with high cost-performance air filtration solutions.

Series Assembly:

To meet more application requirements, we have designed a series of quick combinations suitable for various laboratories or laser cutting, advanced spraying, bottle blowing and other industries.

They can be used directly in series without the need to add threads.

Case

After submitting the information, an engineer will contact you

INQUIRY

INQUIRY DOWNLOAD

DOWNLOAD

Join us

Join us After-sale service

After-sale service News

News