Performance Advantages of Compressed Air Filter Element

Compressed air systems are critical to a wide array of industrial applications, including manufacturing, food processing, automotive, electronics, and pharmaceuticals. The reliability and efficiency of these systems depend heavily on the quality of compressed air being delivered, and this is where the compressed air filter element plays a pivotal role. Designed to remove contaminants such as oil vapors, water droplets, solid particulates, and micro-organisms, filter elements ensure the integrity, longevity, and performance of compressed air systems. In this blog post, as a high quality air compressor air filter element exporter, Wuxi Yuanmei will share the performance advantages of compressed air filter element for sale.

Compressed Air Filter Element Performance Advantages

Superior Filtration Efficiency

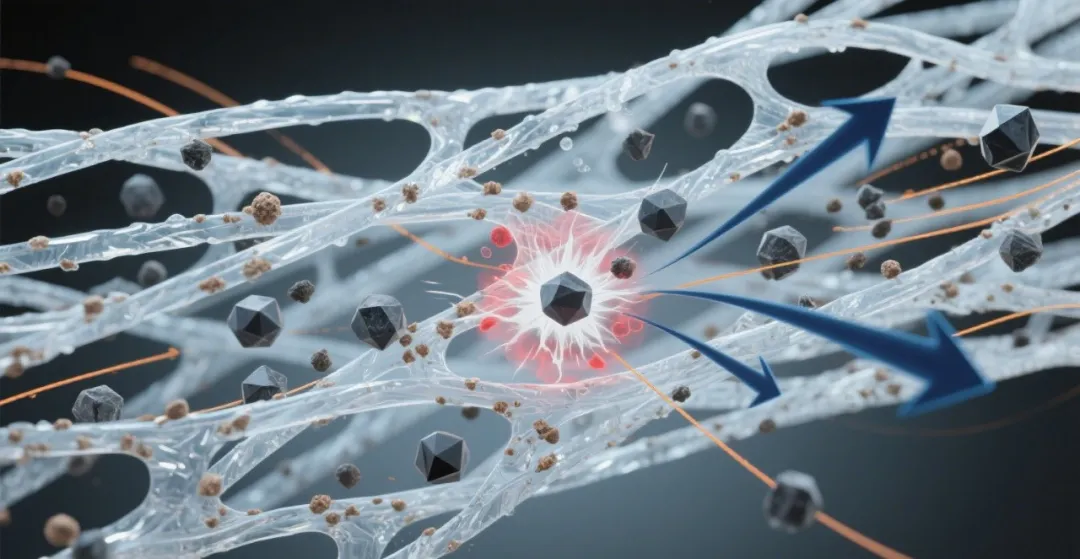

One of the most significant advantages of compressed air filter elements is their high filtration efficiency. These elements are engineered using advanced materials like sintered polymers, borosilicate fibers, or stainless steel mesh, which are capable of capturing particles as small as 0.01 microns.

This high-efficiency filtration is critical in applications that demand ultra-clean compressed air, such as in food packaging or electronics manufacturing. By effectively removing contaminants such as oil aerosols, dust, and water vapor, filter elements help maintain product quality and prevent downstream equipment damage.

Protection of Downstream Equipment

Contaminated compressed air can be extremely harmful to pneumatic machinery, tools, valves, actuators, and instrumentation. Even trace amounts of particulate matter or oil mist can cause corrosion, blockages, or malfunctions.

Compressed air filter elements act as the first line of defense, significantly reducing maintenance costs and minimizing unexpected downtime. Their ability to provide consistent, clean air supply ensures smoother operation and extends the lifespan of critical downstream components.

Improved System Reliability and Productivity

Reliable compressed air systems are essential for maintaining productivity, especially in automated production lines where equipment must run continuously without interruption.

The use of high-performance filter elements guarantees consistent air quality, which in turn minimizes the risk of equipment failure. In operations where even a brief halt can lead to considerable financial losses, investing in reliable filtration solutions provides significant operational assurance.

Energy Efficiency and Pressure Stability

Poorly maintained or inefficient filters can cause pressure drops, leading to increased energy consumption as the system compensates for lost pressure. High-quality compressed air filter elements are designed with optimized flow paths and low differential pressure characteristics to minimize resistance to airflow.

By maintaining stable pressure levels and reducing the load on compressors, these filters contribute to lower energy costs and improved overall system efficiency. Over time, this energy-saving feature becomes a critical cost-saving factor for industries with large-scale compressed air consumption.

Adaptability to Diverse Operating Environments

Compressed air systems are used in a wide variety of environments, ranging from clean rooms to harsh industrial zones. Filter elements are available in different grades and configurations to meet specific application requirements—from coalescing filters for oil removal to particulate filters for dust and solid contaminants.

Some filter elements are constructed to withstand extreme conditions such as high temperatures, corrosive atmospheres, or high flow rates. Their robust design and customizable nature make them highly versatile and suitable for integration into diverse industrial systems.

Easy Maintenance and Replacement

Modern compressed air filter elements are designed not only for performance but also for ease of maintenance. Most models are engineered for quick replacement, often requiring minimal downtime and labor.

Additionally, many high-end filters include visual or electronic indicators to alert operators when a filter needs to be changed, further simplifying the maintenance process. This proactive approach helps prevent system inefficiencies or failures due to clogged or saturated filters.

Contribution to Regulatory Compliance

In industries such as pharmaceuticals, food and beverage, and electronics, maintaining a certain level of air purity is not optional—it is mandated by industry regulations such as ISO 8573-1.

Compressed air filter elements are essential components for achieving and maintaining compliance with air quality standards. By ensuring air purity levels remain within acceptable thresholds, these filters support businesses in meeting regulatory obligations and avoiding penalties or product recalls.

Enhanced Product Quality and Process Integrity

In many manufacturing processes, the quality of compressed air directly influences the final product. For instance, in spray painting, air impurities can result in visible defects. In pharmaceutical production, contamination can compromise the sterility of products.

By delivering contaminant-free compressed air, filter elements help maintain high standards of product quality and process integrity. This is particularly vital in operations where contamination could lead to costly waste or reputational damage.

Long-Term Cost Efficiency

Though high-quality filter elements may present a higher initial investment, they offer long-term economic benefits. Their durability, low pressure drop, and extended service life reduce the frequency of replacements and the risk of equipment damage.

Moreover, when integrated into a comprehensive air management system, these filter elements contribute to optimized performance and reduced total cost of ownership (TCO) over the life cycle of the equipment.

Environmental Benefits

Efficient filtration also brings environmental advantages. By reducing oil and particulate emissions into the atmosphere and lowering energy consumption, compressed air filter elements support corporate sustainability initiatives. Many filters are also recyclable, aligning with industry efforts toward more eco-friendly practices.

Conclusion

Compressed air filter elements are far more than simple accessories; they are critical performance enhancers for industrial air systems. From improving air purity and protecting equipment to lowering energy costs and supporting regulatory compliance, their advantages are manifold.

Join us

Join us After-sale service

After-sale service News

News