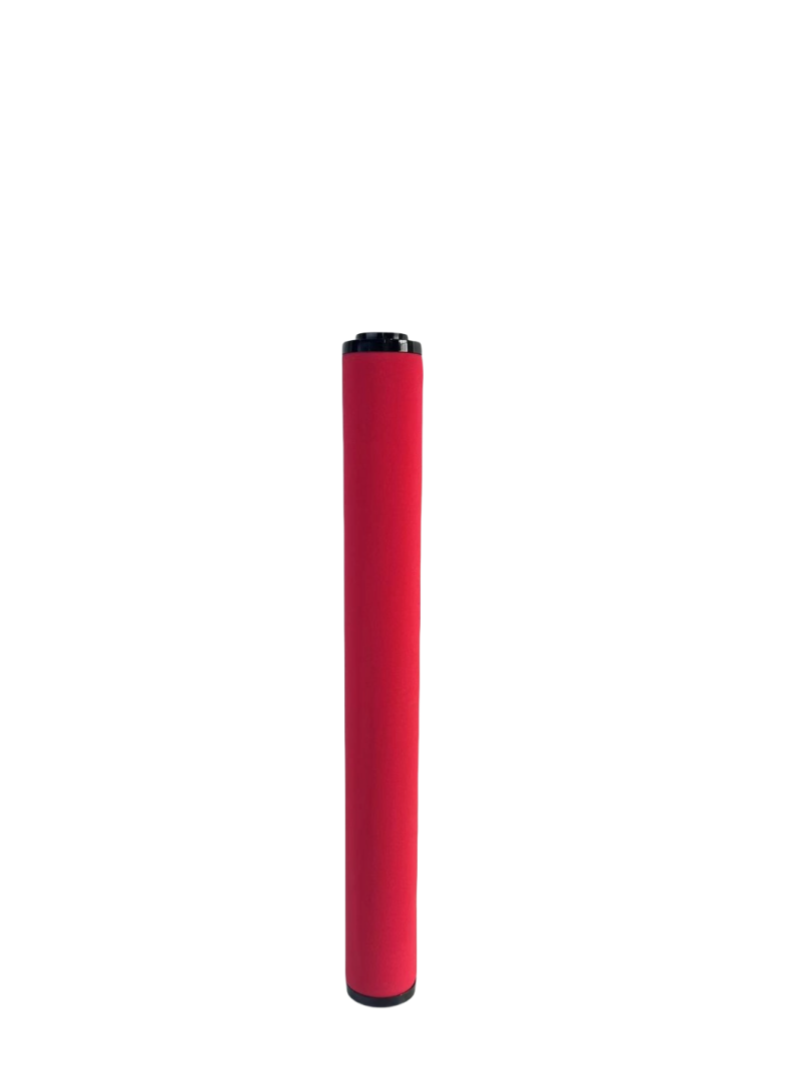

Product Details:

Origin: Wuxi, Jiangsu, China

Life Time: 8,000h

Pressure Loss: ≤0.011bar (5-7% energy saving)

Stock: Main models shipped in 24h

Custom: OEM drawing service

Applications: Laser cutting, electronics, sandblasting

Certification marks: ISO8573-1、 CE、 RoHS

Payment & Shipping Terms:

MOQ: 1 pcs

Price: Online contact

Packaging: Plastic bag-box-cartons/pallets or Custom options

Payment:100% T/T(RMB/USD)

Supply Capacity: 1000+ pcs

INQUIRY

INQUIRY DOWNLOAD

DOWNLOAD

Join us

Join us After-sale service

After-sale service News

News