YM Model | YM067066 |

Original Filter Brand | INGERSOLL-2424 |

Original Model | 24242497 |

Precision / Residual oil amount | 1μm |

Processing capacity | 30.6 Nm³ / min |

Working Temperature | 1.5 ~ 80℃ |

Working Pressure | 0.1 ~ 2.0Mpa |

Media | Micro fiberglass |

End Caps | Engineering plastic |

Seal | Buna-N |

Weight (including packaging) Weight (including packaging)

| 1.35 kg |

Size packaging(cm) | 48*16.5*16.5 2424 3 # |

Dimensions(mm) |

| D | H |

|

|

|

| 117±1 | 450±2 |

|

|

Country of Origin / HTS Code | CHINA / 8421999090 |

Notes | Please consult WUXI Yuanmei sales personnel for any remaining areas |

Key Advantages

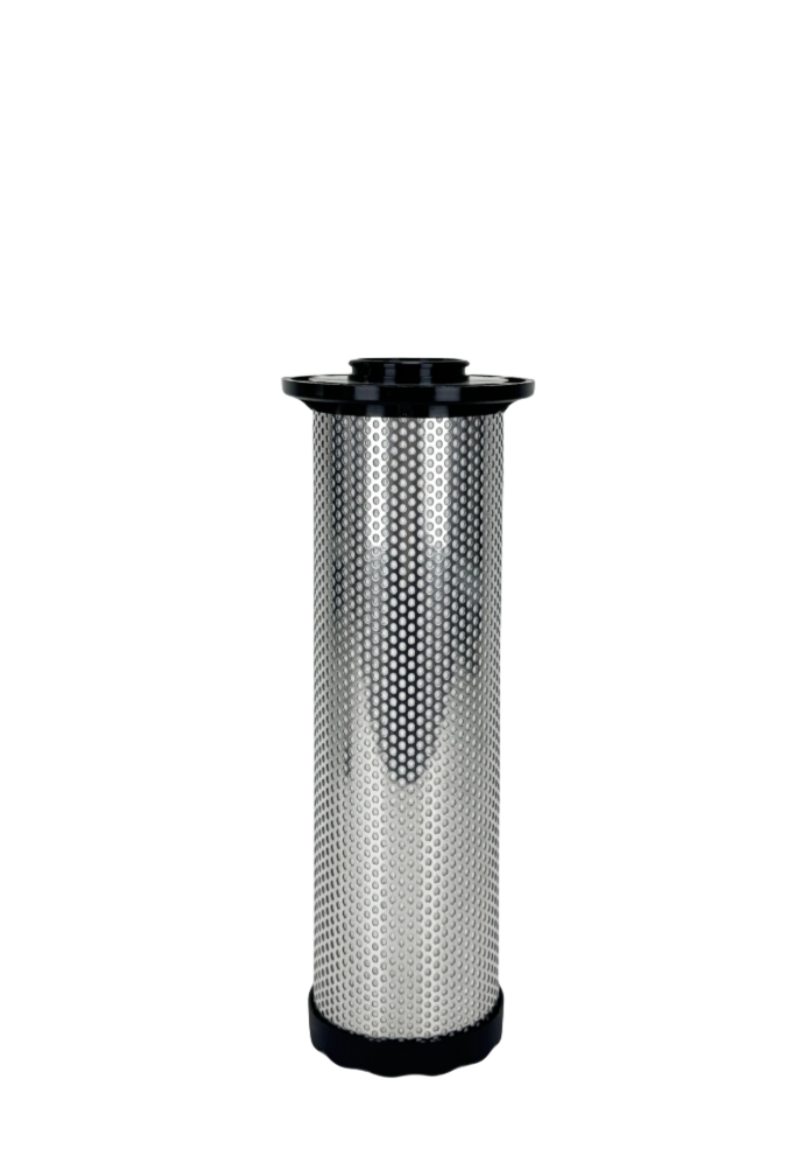

The IngersollRand 24242497 replacement filter element is engineered for reliable air purification in demanding compressed-air systems. Manufactured in Wuxi, Jiangsu, China, this filter cartridge is designed to provide stable filtration efficiency throughout its 8,000-hour service life, minimizing downtime and maintenance frequency. By controlling pressure drop within ≤0.011 bar, the filter helps reduce energy consumption by approximately 5–7%, making it a cost-effective choice for long-term operation.

A major advantage of this substitute filter element is its compatibility with the original INGERSOLL-2424 housing, eliminating the need for equipment modification. With a processing capacity of 30.6 Nm³/min, it supports high-volume airflow while maintaining consistent filtration performance for sensitive industrial environments. Additionally, customers benefit from fast dispatch, as main models are available for 24-hour shipping, ensuring uninterrupted operation for factories and service providers.

The product is supported by important certifications such as ISO8573-1, CE, and RoHS, offering assurance of quality, environmental compliance, and suitability for international markets.

Core Features

Designed with a 1 μm precision rating, the filter element effectively captures fine particulate matter and residual oil content, safeguarding downstream equipment and improving the lifespan of pneumatic tools, laser cutters, and sensitive electronics. The filtration media consists of micro fiberglass, known for its uniform pore structure, high contaminant-holding capacity, and stable thermal performance under varying load conditions.

Structural durability is enhanced by engineering-grade plastic end caps, providing consistent dimensional accuracy and corrosion resistance. The filter also uses Buna-N sealing, ensuring secure airtight performance across a working pressure range of 0.1–2.0 MPa. Its reliable sealing structure helps maintain system integrity even in fluctuating temperature environments from 1.5°C to 80°C.

Dimensionally, the cartridge is precisely crafted to match OEM standards, with measurements of 117 ±1 mm (diameter) and 450 ±2 mm (height). Each filter element weighs 1.35 kg including packaging, and comes in a 48 × 16.5 × 16.5 cm protective box for safe transportation. OEM customization and drawing services are available for customers requiring tailored solutions.

Diverse Applications

The 24242497 compatible air filter element is widely adopted across industries requiring clean, stable compressed air. In laser cutting systems, high-purity air contributes to consistent beam quality, clean cutting edges, and extended machine uptime. The filter’s fine particulate retention helps protect optical components from contamination.

In electronics manufacturing, where precise assembly and dust-sensitive processes demand exceptionally clean air, the filter supports controlled environments by reducing micro-contaminants and oil vapors. Production lines such as PCB assembly, semiconductor packaging, and automated testing equipment benefit significantly from its uniform filtration performance.

The filter element is also suitable for sandblasting operations, where maintaining dry, contaminant-free air is crucial for abrasive flow stability and surface treatment quality. Additionally, it can be applied in general industrial sectors including pneumatic automation, painting systems, CNC machinery, and equipment requiring dependable compressed-air purification.

With a supply capability exceeding 1,000 pieces, the product is well-positioned for distributors, service centers, and industrial users needing stable procurement for continuous operations.

User Value & Benefits

Users adopting the replacement filter for IngersollRand 24242497 gain a cost-efficient, high-performance solution without compromising quality. The low pressure drop directly translates to reduced compressor load, enabling measurable energy savings. The long 8,000-hour service span minimizes change-out intervals, lowering labor costs and maintenance budgets.

The filter’s advanced fiberglass media enhances system reliability by preventing contamination of valves, actuators, and precision tools. Improved air quality leads to optimized equipment performance, reduced reject rates in manufacturing processes, and higher overall production efficiency.

Its compliance with ISO8573-1, CE, and RoHS adds global credibility, ensuring safety and compatibility in facilities governed by strict quality systems. For operations requiring quick turnaround, the availability of ready-to-ship inventory ensures minimal delays, while OEM drawing support assists customers needing non-standard configurations.

Flexible ordering is supported, with an MOQ of 1 piece, transparent T/T payment options in RMB or USD, and customizable packaging including cartons, pallets, and private-label designs. With a HS code of 8421999090, the filter is easy to export and integrate into global supply chains.

For further technical assistance or project-specific requests, customers may consult WUXI Yuanmei sales personnel for professional guidance.

INQUIRY

INQUIRY DOWNLOAD

DOWNLOAD

Join us

Join us After-sale service

After-sale service News

News