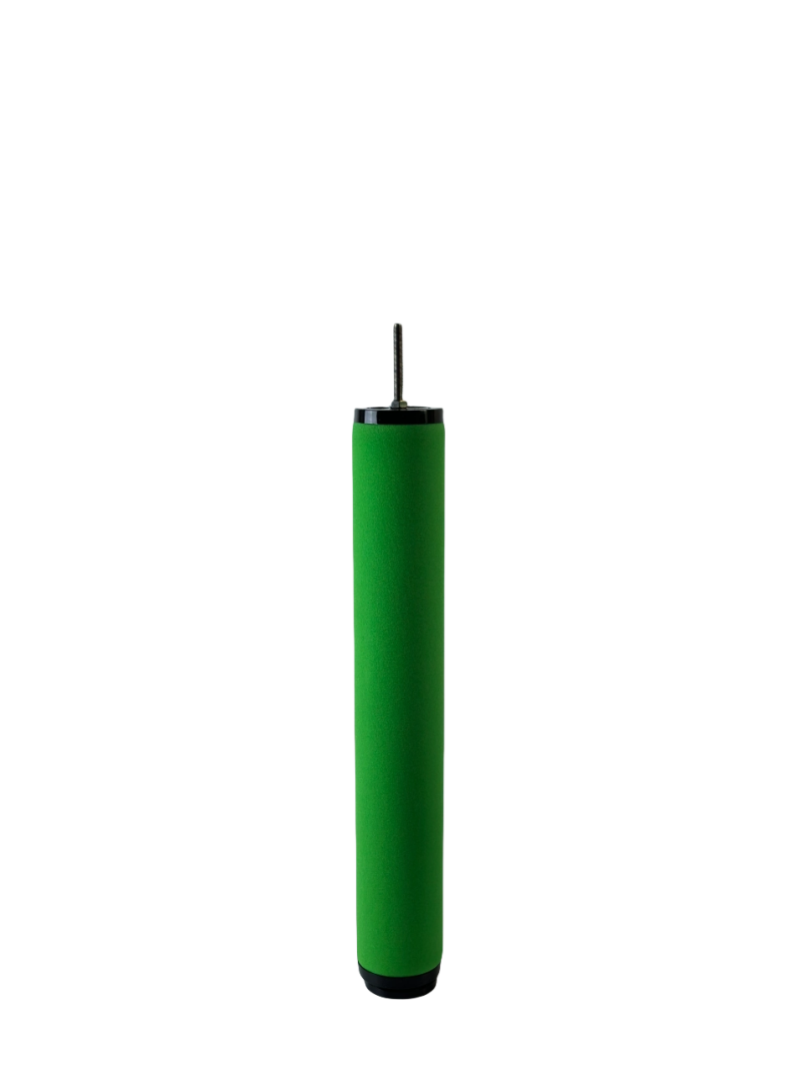

YM Model | YM043051 |

Original Filter Brand | KAESER |

Original Model | E-G-107 |

Precision / Residual oil amount | 0.01μm / 0.003 ppm |

Processing capacity | 11.0 Nm³ / min |

Working Temperature | 1.5 ~ 80℃ |

Working Pressure | 0.1 ~ 2.0Mpa |

Media | Activated carbon |

End Caps | Engineering plastic |

Seal | Buna-N |

Weight (including packaging) Weight (including packaging)

| 0.95kg |

Size packaging(cm) | 54.5*7.5*7.5 E-36 # |

Dimensions(mm) |

| D | H |

|

|

|

| 68±1 | 450±2 |

|

|

Country of Origin / HTS Code | CHINA / 8421999090 |

Notes | Please consult WUXI Yuanmei sales personnel for any remaining areas |

Key Advantages

The KAESER E-G-107 replacement filter element is engineered to maintain consistent compressed-air purity across demanding operating conditions. Designed as a high-precision substitute for the original filter cartridge, it delivers stable filtration efficiency, helping facilities protect downstream equipment and maintain uninterrupted air quality. Its optimized structure minimizes flow resistance, ensuring equipment runs with greater energy efficiency. This replacement filter element also reduces operational risks caused by particulate or oil contamination, making it an effective and cost-controlled solution for long-term system reliability.

Another significant advantage is its dependable performance retention across extended service intervals. The KAESER E-G-107 filter element is built to withstand continuous air-pressure fluctuations, enabling users to maintain cleaner air output without frequent replacements. This contributes to both operational stability and reduction of maintenance burdens.

Core Features

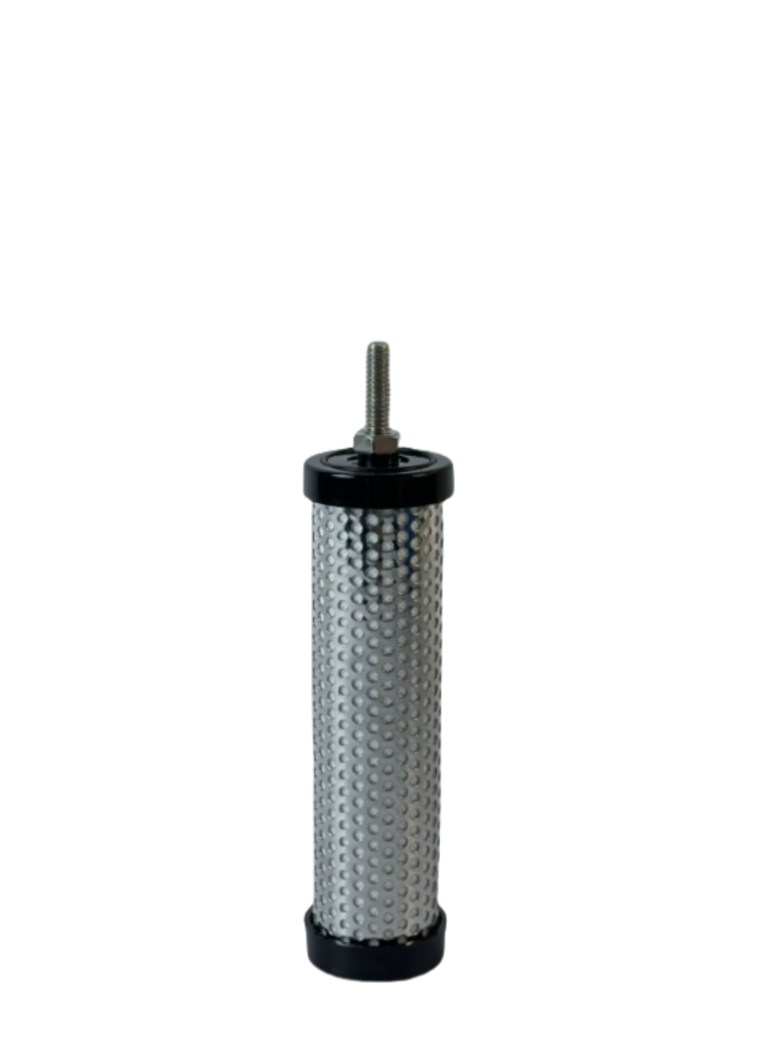

The replacement filter element for KAESER E-G-107 incorporates a multi-layer filtration media structure that targets fine particulates and residual oil aerosols. Each layer is designed to capture contaminants at different micron levels, ensuring high-grade air filtration while maintaining low pressure drop. The rigid outer cage improves structural durability, enabling the filter to maintain shape and efficiency even under high airflow and temperature variations.

Its sealing components are engineered to ensure a tight fit within the housing, preventing bypass and ensuring that all compressed air flows through the filtration media. Precision manufacturing standards ensure dimensional consistency, making installation seamless for end-users. Advanced resin-bonded fibers enhance contaminant retention, allowing the element to sustain performance for longer periods compared to generic substitutes.

Additionally, this E-G-107 filter replacement meets industrial expectations for corrosion resistance and mechanical strength. The careful material selection supports stable performance in environments exposed to moisture, oil vapor, or fine dust. These design elements collectively elevate the filter’s reliability across diverse applications.

Diverse Applications

The KAESER E-G-107 filter element replacement is suitable for a wide range of compressed-air systems in industrial and commercial fields. Manufacturers rely on it to maintain clean air for pneumatic tools, assembly operations, and automated production lines. In electronics and precision engineering, its filtration capability supports processes that require extremely low contamination levels to prevent product defects.

In petrochemical facilities, the element helps maintain consistent compressed-air purity, ensuring the protection of sensitive valves and instruments. Food and beverage processors use this filter element to safeguard air contact points and reduce contamination risks. The E-G-107 replacement filter cartridge is also utilized in pharmaceutical production, where controlled air quality is essential for maintaining regulatory compliance.

It also serves critical roles in packaging plants, automotive workshops, CNC machine operations, and general compressed-air treatment tasks. The filter’s robust construction and efficient contaminant control make it suitable for both continuous-duty systems and intermittent-load compressors. With its adaptable performance, the KAESER E-G-107 replacement supports clean and stable airflow across a broad spectrum of operational scenarios.

User Value & Benefits

Choosing a replacement filter for KAESER E-G-107 brings measurable value to end-users seeking improved operating efficiency and reduced long-term costs. Its advanced filtration performance protects air-powered machinery, minimizing wear and extending equipment service life. Fewer equipment malfunctions translate directly to lower repair expenses and fewer production interruptions.

Users also benefit from reduced energy consumption. By maintaining low differential pressure, the E-G-107 replacement filter reduces the workload on air compressors, helping facilities achieve more efficient operation. This contributes to energy savings while still supporting consistent airflow quality.

The filter’s stability over extended use also minimizes the need for frequent replacements. This reduces inventory requirements, maintenance time, and overall operating costs. The combination of dependable filtration accuracy and durable material selection ensures long-lasting performance that supports cleaner, safer, and more reliable air supply.

Furthermore, the KAESER E-G-107 replacement filter element offers enhanced peace of mind by maintaining compliance with air-quality standards required in sensitive production environments. Its consistent contaminant retention ensures that businesses can confidently meet internal quality controls and external regulatory expectations.

INQUIRY

INQUIRY DOWNLOAD

DOWNLOAD

Join us

Join us After-sale service

After-sale service News

News