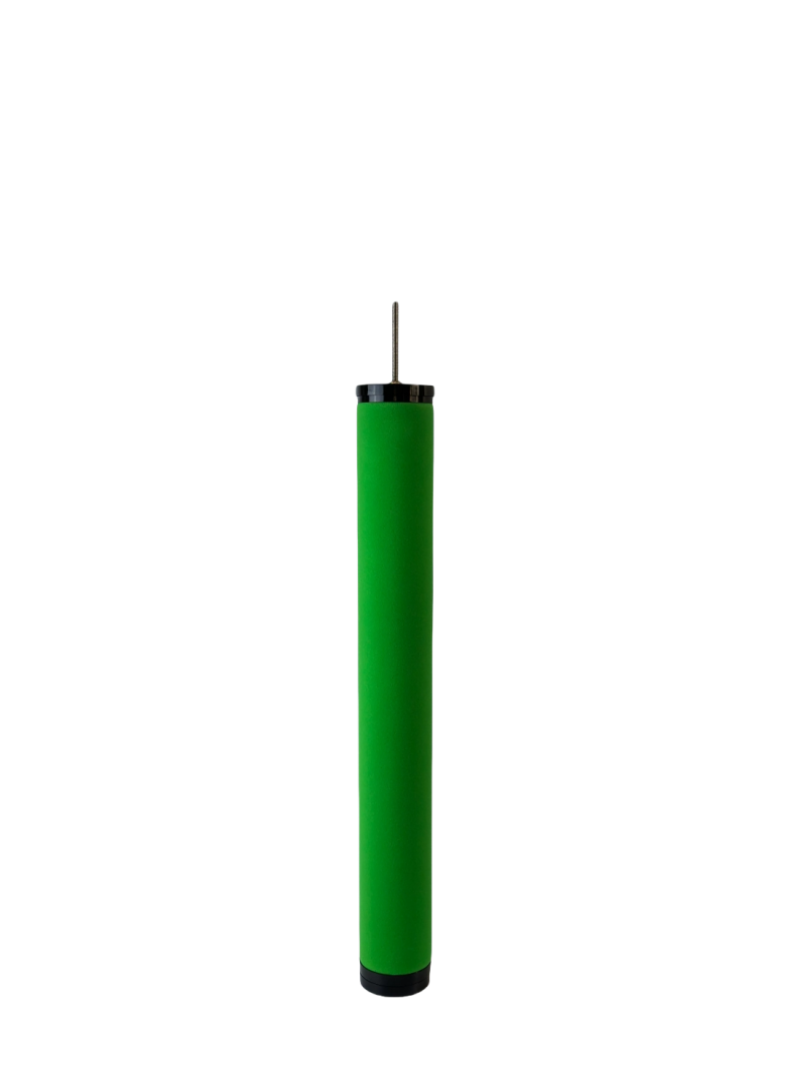

YM Model | YM043054 |

Original Filter Brand | KAESER |

Original Model | E-G-185 |

Precision / Residual oil amount | 0.01μm / 0.003 ppm |

Processing capacity | 20.0 Nm³ / min |

Working Temperature | 1.5 ~ 80℃ |

Working Pressure | 0.1 ~ 2.0Mpa |

Media | Activated carbon |

End Caps | Engineering plastic |

Seal | Buna-N |

Weight (including packaging) Weight (including packaging)

| 1.85kg |

Size packaging(cm) | 79*9.5*9.5 E- 44 # |

Dimensions(mm) |

| D | H |

|

|

|

| 83±1 | 667±2 |

|

|

Country of Origin / HTS Code | CHINA / 8421999090 |

Notes | Please consult WUXI Yuanmei sales personnel for any remaining areas |

Key Advantages

The KAESER E-G-185 replacement filter element delivers precision-engineered air filtration for industrial systems requiring high purity and reliability. Designed as a direct alternative to the original KAESER E-G-185 model, this advanced filter ensures optimal performance while maintaining energy efficiency and consistent air quality. With a low pressure drop of ≤0.011 bar, it helps reduce compressor energy consumption by up to 7%, contributing to lower operational costs and environmental sustainability. Its extended 8,000-hour service life provides exceptional durability, minimizing maintenance downtime and maximizing equipment uptime for critical production environments.

Core Features

Each E-G-185 replacement filter cartridge is meticulously built from high-efficiency activated carbon media, ensuring fine particle filtration down to 0.01 μm and an oil residual content as low as 0.003 ppm. The engineering plastic end caps guarantee dimensional stability and chemical resistance, even under fluctuating operating pressures from 0.1 to 2.0 MPa and temperatures ranging between 1.5°C and 80°C.

The Buna-N sealing system provides superior air-tight performance, preventing leakage and ensuring reliable filtration efficiency throughout the product’s lifespan. With a compact structure and precise dimensions (D 83±1 mm / H 667±2 mm), the filter ensures a perfect fit and easy replacement. OEM customization is available according to technical drawings, making it adaptable for a wide range of compressed air purification systems.

Furthermore, each unit undergoes strict ISO and CE-certified quality inspection, ensuring compatibility and consistent performance across industrial applications. Main models are available in stock and can be shipped within 24 hours, meeting urgent maintenance or replacement needs.

Diverse Applications

The KAESER E-G-185 filter element is widely used in laser cutting systems, electronics manufacturing, and sandblasting operations, where clean, dry, and oil-free compressed air is essential for product integrity and system efficiency. It also performs reliably in pharmaceutical, food packaging, and precision machining environments, supporting high standards of contamination control.

This replacement filter can be integrated into air compressor lines, air dryers, and vacuum systems where KAESER original filters are used, ensuring seamless interchangeability without performance loss. Its activated carbon media efficiently removes oil vapors, odors, and hydrocarbons, protecting downstream equipment and maintaining the purity of compressed air used in sensitive production processes.

User Value & Benefits

By selecting the KAESER E-G-185 replacement filter element, users benefit from a perfect balance of filtration precision, reliability, and cost-effectiveness. Its low energy consumption contributes directly to reduced operating expenses, while the long service life minimizes maintenance frequency. The use of high-grade filtration materials ensures consistent air quality, extending the life of pneumatic tools and machinery.

The OEM-compatible design and customization options further enhance versatility for varied industrial setups. Supported by professional technical service from Wuxi Yuanmei, users can rely on efficient order processing, secure packaging (plastic bag–box–carton/pallet), and flexible payment terms (100% T/T in RMB or USD).

Ultimately, this KAESER E-G-185 filter replacement is a trusted solution for maintaining system efficiency, environmental compliance, and production stability—ensuring that every cubic meter of compressed air meets the highest purity standards.

INQUIRY

INQUIRY DOWNLOAD

DOWNLOAD

Join us

Join us After-sale service

After-sale service News

News