YM Model | YM054045 |

Original Filter Brand | Parker EcoPure |

Original Model | E400-AC |

Precision / Residual oil amount | 0.01μm / 0.003 ppm |

Processing capacity | 40.0 Nm³ / min |

Working Temperature | 1.5 ~ 80℃ |

Working Pressure | 0.1 ~ 2.0Mpa |

Media | Activated carbon |

End Caps | Engineering plastic |

Seal | Buna-N |

Weight (including packaging)

| 1.5 kg |

Size packaging(cm) | 61*13.5*13.5 7 # |

Dimensions(mm) | | D | H | | |

| | 117±1 | 558±2 | | |

Country of Origin / HTS Code | CHINA / 8421999090 |

Notes | Please consult WUXI Yuanmei sales personnel for any remaining areas |

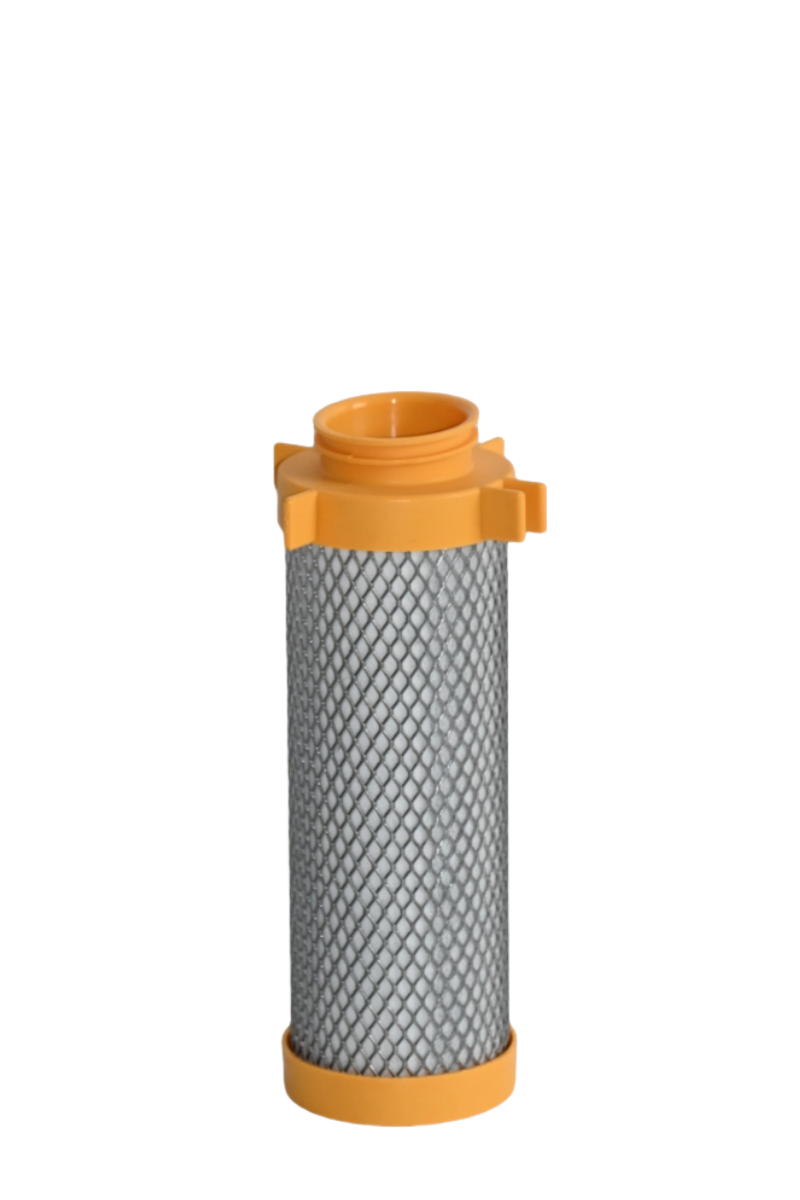

Parker EcoPure E400-AC Replacement Filter Element is a high-performance compressed air filtration solution designed for precision industrial environments. Manufactured in Wuxi, Jiangsu, China, this replacement element meets the original Parker EcoPure E400-AC specifications while delivering stable purification efficiency, low pressure loss, and long service life. It is ideal for users seeking a reliable alternative with consistent quality and fast availability.

Key Advantages

The Parker EcoPure E400-AC replacement filter element is engineered for applications where oil vapor removal and air purity are critical. Using high-grade activated carbon media, it achieves a filtration precision of 0.01 μm and a residual oil content as low as 0.003 ppm. This ensures compliance with ISO 8573-1 air quality standards and protects downstream equipment.

Another advantage is its low pressure loss (≤0.011 bar), which contributes to energy savings of 5–7% by reducing compressor workload. With a rated lifetime of up to 8,000 hours, maintenance frequency is minimized, lowering total operating costs.

Main models are available for shipping within 24 hours, reducing downtime for industrial systems.

Core Features

This replacement element is fully compatible with the original Parker EcoPure E400-AC. It supports a processing capacity of 40.0 Nm³/min, ensuring stable airflow under demanding conditions.

Key components include activated carbon filtration media for consistent adsorption, engineering plastic end caps for structural strength, and a Buna-N seal to maintain airtightness across a working pressure range of 0.1–2.0 MPa. The element operates reliably between 1.5°C and 80°C and weighs approximately 1.5 kg including packaging.

The product meets CE and RoHS certifications, and OEM drawing services are available for customized dimensions or specifications.

Diverse Applications

The Parker EcoPure E400-AC replacement filter element is suitable for industries requiring ultra-clean compressed air. In laser cutting systems, it prevents lens contamination and ensures precise operation. In electronics manufacturing, it avoids defects in sensitive components. For sandblasting, it removes oil vapor and odors to improve surface treatment consistency.

Its performance is also relevant for other applications that need oil-free and odor-free air, including precision instrumentation, coating lines, and automated production processes.

User Value & Benefits

Users benefit from a combination of energy efficiency, long service life, and reliable oil vapor removal. These features reduce maintenance needs and operating costs over time.

With a minimum order quantity of one piece and a supply capacity exceeding 1,000 units, the filter supports both small and large-scale operations. Flexible packaging options—plastic bag, box, carton, pallet, or custom solutions—facilitate storage and transport.

Professional technical support is available through WUXI Yuanmei sales personnel, ensuring proper integration and guidance for any application. Overall, the Parker EcoPure replacement filter element balances performance, reliability, and operational efficiency, making it a practical choice for maintaining high-quality compressed air in industrial environments.

INQUIRY

INQUIRY DOWNLOAD

DOWNLOAD

Join us

Join us After-sale service

After-sale service News

News