Testing Equipment:

The company has a dedicated testing laboratory and has introduced the German equipment-CS 0.1.

The testing requirements can meet the ISO-8573-1:2010 Class 1 standard

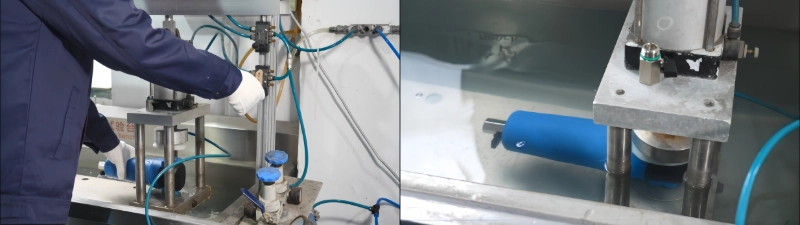

Air tightness test:

Before each filter leaves the factory, a 100% water pressure test for air leakage points must be conducted to ensure there is no energy leakage during use.

(Sampling for testing is strictly prohibited.)

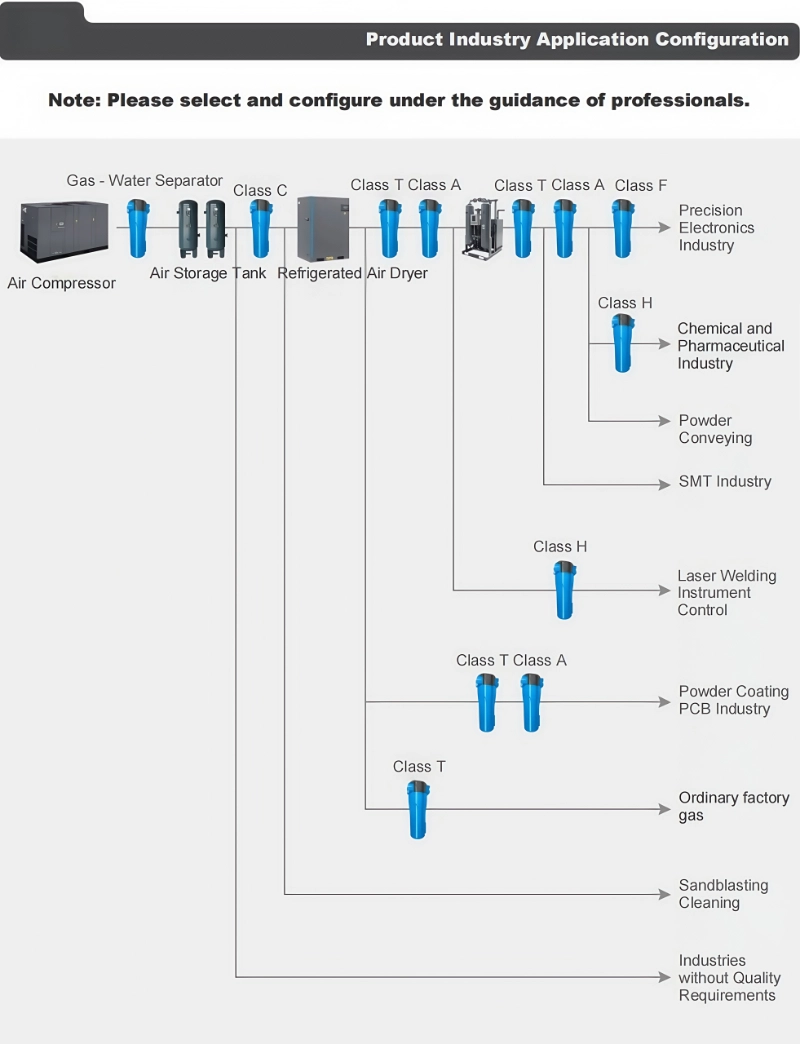

Widely applicable:

Precision manufacturing: Laser cutting, precision electronics, and automated equipment

Surface treatment: Advanced spraying, sandblasting

Packaging and shaping: Bottle blowing

Life and health: Food and beverage, medical and pharmaceutical, clean laboratory

Industrial general: mechanical welding, mining, workshops, pneumatic tools, petrochemicals, etc

Through multi-industry application verification, this series of products can effectively enhance equipment operation efficiency, reduce failure rates, and extend maintenance cycles. It adopts a modular design, is easy to install, has low maintenance costs, and is compatible with equipment of various brands. The product has passed the ISO9001 quality system certification and complies with international standards such as CE and RoHS, providing customers with high cost-performance air filtration solutions.

Series Assembly:

To meet more application requirements, we have designed a series of quick combinations suitable for various laboratories or laser cutting, advanced spraying, bottle blowing and other industries.

They can be used directly in series without the need to add threads.

Case

After submitting the information, an engineer will contact you

INQUIRY

INQUIRY DOWNLOAD

DOWNLOAD

Join us

Join us After-sale service

After-sale service News

News