Compressor Air Line Filter Selection Guide for Industrial Systems

Compressed air quality directly impacts the performance, longevity and compliance of industrial systems. For procurement teams and technical engineers around the world, selecting the appropriate air line filter for compressor installations is not only a technical necessity but also a key determinant of operational efficiency, risk mitigation, and lifecycle cost. In this blog post, Yuanmei, as one of the high quality precision air compressor filter manufacturers, will share the importance of air line filter for compressor in industrial systems.

Air Contaminants That Make Filtration Essential

Compressed air systems draw ambient air that inevitably contains particulate contaminants, water vapor, lubricant aerosols and other trace elements. During compression these contaminants become concentrated, often accelerating equipment wear and diminishing air quality downstream. Industrial air line filters mitigate these effects by capturing solids, liquid droplets and oil aerosols before distribution into critical systems. In environments where product integrity or compliance is essential, effective filtration is mandatory.

Aligning Compressor Filtration with ISO 8573‑1 Air Quality Standards

One of the most important benchmarks when selecting filtration solutions is the ISO 8573‑1 compressed air quality standard. This framework classifies compressed air across three key parameters: particles, moisture and oil content. Each compressed air system application calls for a defined purity class based on operational requirements. Moisture levels and oil residues must be tightly controlled in pharmaceutical lines, while automotive paint systems have strict particulate and dew point requirements.

Understanding these purity classes helps procurement and engineering teams specify appropriate air line filters that meet or exceed compliance expectations in global markets.

Key Performance Indicators for Compressor Air Line Filters

Industrial filtration performance is evaluated with several key indicators:

• Pressure drop across the filter – Lower differential pressure is essential for maintaining compressor efficiency

• Filter efficiency and media rating – Determines the ability to capture specific particle sizes or aerosols

• Operating temperature and phase stability – Ensures filter media remains effective under expected conditions

• Service life and element replacement intervals – Impacts maintenance planning and total cost of ownership

These metrics form the backbone of any procurement specification when evaluating air line filter for compressor options.

Technical Specification Table for Common Filter Performance Metrics

| Parameter | Typical Industrial Target |

|---|---|

| Micron Rating | 0.01 to 5 microns (depending on contaminant type) |

| Recommended Dew Point for Critical Environments | −40°C to −70°C |

| Pressure Drop (new filter) | < 0.3 bar / 4.3 PSI |

| Oil Carry‑Over Limits | < 0.1 to 0.01 mg/m³ for stringent applications |

| Service Life Indicator | Visual/pressure differential measurement points |

Values should be aligned with system flow requirements and compliance targets.

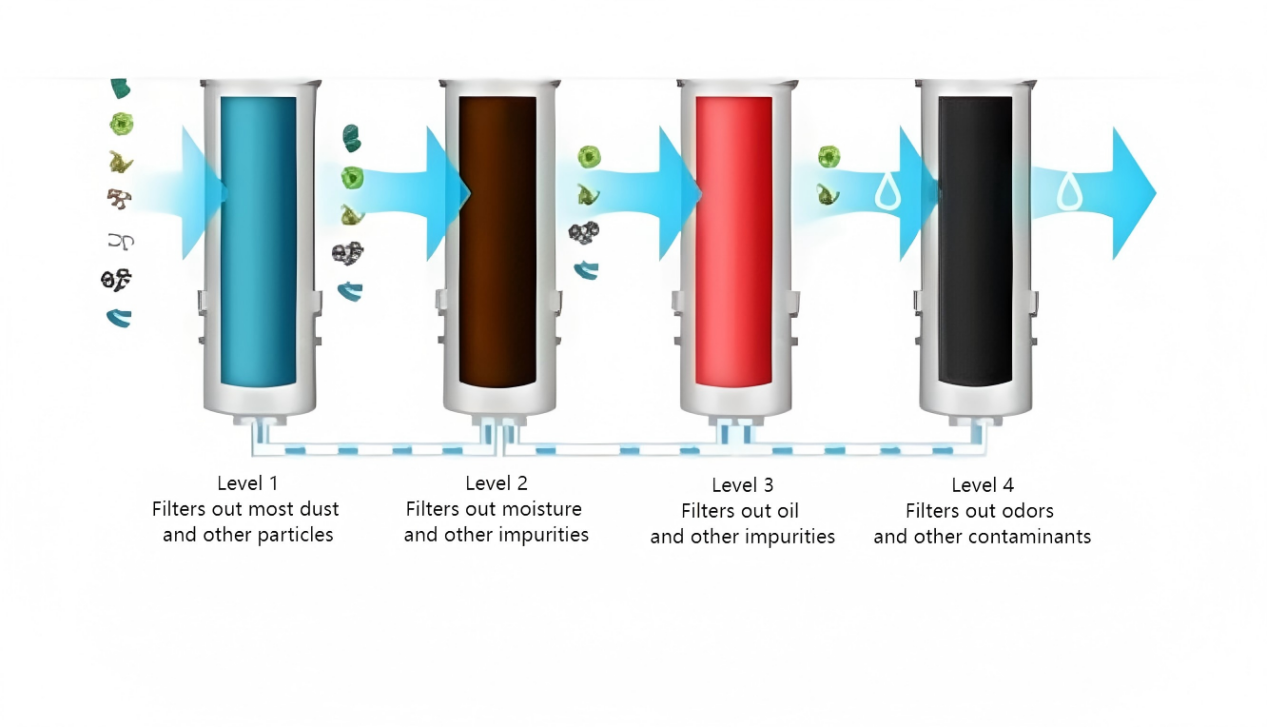

Multi‑Stage Filtration Strategies in Compressor Networks

Effective filtration often uses a combination of components:

• Pre‑filtration units for coarse particulate removal

• Coalescing filters for moisture and fine aerosol management

• Activated carbon or specialized media for oil vapor and microscopic contaminants

This layered approach enhances air purity, reduces element clogging, and increases service life.

Installation Practices That Affect Air Line Filter Performance

Proper installation is critical:

• Place filtration close to the point of use to minimize recontamination

• Use automatic condensate drains to manage moisture efficiently

• Ensure upstream dryers and separators complement filter capacity

• Maintain proper piping layout to prevent leaks and bypass

Correct installation directly impacts real-world performance.

Balancing Operational Efficiency With Filtration Needs

Filtration adds resistance to airflow, impacting energy consumption and compressor cycling. Filters with optimized media and low pressure drop characteristics help maintain efficiency. Matching filter capacity to compressor flow prevents excessive pressure loss or underutilization, both of which can affect operational cost and uptime.

Global Compliance and Documentation

International buyers must consider regulatory and compliance frameworks beyond performance ratings. ISO certification, tested ratings, and documented performance validation provide confidence in supply chains and support quality audits. Transparent documentation ensures filters meet international standards and reduces procurement risk.

Maintenance, Monitoring, and Predictive Practices

Lifecycle management increasingly includes sensors tracking differential pressure, filter saturation, and condensate dynamics. Predictive maintenance reduces unplanned downtime and ensures higher system reliability. Facilities integrating monitoring tools experience measurable gains in uptime and efficiency.

Vendor Evaluation Criteria for Industrial Buyers

Key criteria when evaluating suppliers include:

• ISO performance verification

• Technical support and engineering consultation

• Lifecycle cost including replacement and service intervals

• Regional service and parts availability

Selecting partners that provide transparent performance data improves operational outcomes and mitigates supply chain risks.

Emerging Trends in Compressor Filtration

Advanced filter media and smart monitoring are driving adoption of predictive maintenance strategies. Industries like electronics, pharmaceuticals, and aerospace are increasingly demanding high-efficiency, ISO-compliant air line filter for compressor solutions to reduce downtime and meet compliance targets.

FAQ

What is the main purpose of an air line filter in compressor systems?

Air line filters remove particulate, moisture and oil contaminants from compressed air to prevent equipment damage and maintain product quality.

How does ISO 8573‑1 affect filter selection?

It defines compressed air purity classes that determine the choice and configuration of filtration media.

Why is pressure drop important for air line filters?

Pressure drop affects compressor efficiency and energy consumption. Filters must balance contaminant removal with minimal resistance.

What should buyers consider beyond technical specifications?

Documentation, compliance certifications, service support, total lifecycle costs, and lead times are critical factors.

Where can industry data on filtration standards be found?

ISO 8573‑1 and related test methods provide authoritative guidance for filter performance specifications.

Join us

Join us After-sale service

After-sale service News

News