Proper Maintenance of Precision Compressed Air Filters

In modern industrial environments, precision compressed air filters play a pivotal role in ensuring clean and stable airflow for pneumatic systems and high-precision equipment. Despite their importance, many users lack professional maintenance knowledge, leading to reduced filter life, equipment malfunctions, and even secondary contamination of air. This guide delves into practical maintenance strategies, helping you optimize the performance and longevity of your filters while ensuring consistent air quality. In this blog post, Wuxi Yuanmei, a high quality industrial compressed air filter manufacturing factory, will share information on the proper maintenance of precision compressed air filters.

Importance of Precision Compressed Air Filters in Industrial Applications

Precision compressed air filters are essential components in industries where clean air directly impacts product quality and operational efficiency. These filters are commonly used in machining, electronics manufacturing, food processing, pharmaceuticals, and emerging sectors like new energy technology.

A well-maintained industrial compressed air filter not only protects downstream equipment but also prevents contamination that can affect sensitive processes. Impurities such as solid particles, oil mist, and water condensate can reduce the efficiency of pneumatic systems, damage machinery, and compromise the quality of manufactured products. Ensuring proper maintenance and timely replacement is therefore critical for uninterrupted operations.

Cartridge Maintenance and Pre-operation Inspection

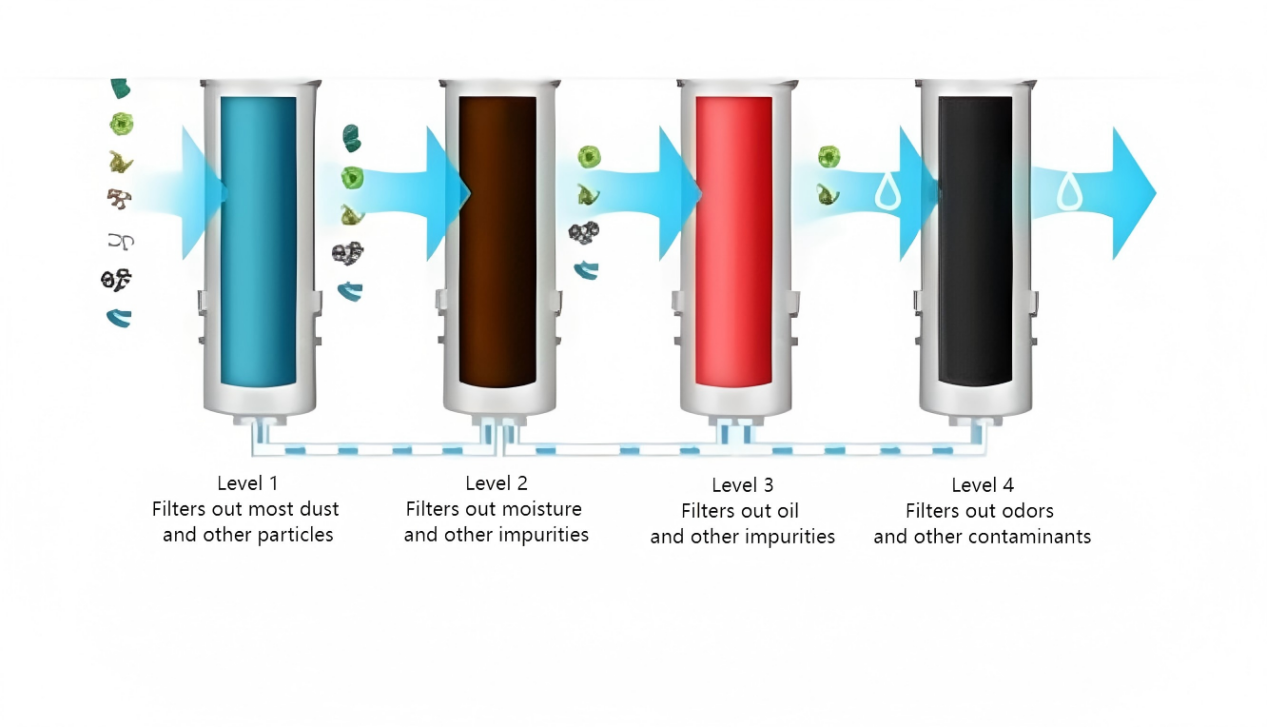

Cartridges are the core wear components of precision compressed air filters, often made from materials like glass fiber, activated carbon, and sintered metal. These elements are responsible for removing contaminants and ensuring the air meets required purity standards.

Before starting your pneumatic systems, it is vital to inspect the cartridges carefully. Check for signs of:

Physical damage or deformation

Aging or compromised seals

Proper alignment and tight installation

Incorrect installation or worn-out cartridges can allow unfiltered air to enter downstream systems, potentially causing equipment damage or contamination of sensitive products. Regular pre-operation inspection is a fundamental practice recommended by compressed air filter manufacturers to maintain both performance and safety.

Contaminant Removal and Timely Cartridge Replacement

Over time, precision compressed air filters accumulate dust, oil mist, and condensed water, which can clog the cartridge and reduce airflow. A significant increase in pressure drop or abnormal airflow can indicate that the filter is approaching the end of its service life.

Key maintenance practices include:

Monthly cleaning of filter housings and drains under normal operating conditions

Immediate replacement of cartridges when the inlet-outlet pressure difference reaches 0.07–0.1 MPa or manual thresholds are exceeded

Replacement of cartridges if air quality tests detect dust or oil beyond acceptable limits

Using expired or non-genuine cartridges can compromise air quality and may even void manufacturer warranties. Maintaining proper compressed air filter hygiene ensures both energy efficiency and consistent downstream equipment protection.

Wear Monitoring and Detailed Maintenance

Beyond the cartridges, other components of industrial compressed air filters—such as housings, seals, and valves—experience wear and tear over time. This degradation can cause unstable airflow, reduced filtration efficiency, and equipment strain.

To prevent issues, implement a detailed monitoring routine:

Inspect housings for corrosion, cracks, or deformation

Check seals and gaskets for integrity to avoid leaks

Monitor flow rate and pressure differences regularly

Keep the surrounding area clean to prevent dust and oil buildup that affects heat dissipation

Proactive maintenance not only extends the life of the filter system but also ensures optimal performance of downstream equipment.

Understanding Common Filtration Challenges

Even with proper maintenance, precision compressed air filters can face operational challenges that require attention:

Clogging: Particles and oil can accumulate faster in high-humidity or dusty environments, increasing pressure drop.

Seal Failure: Aging seals can lead to bypass leakage, allowing contaminants into the system.

Condensate Management: Inadequate drainage can lead to water accumulation, promoting microbial growth and corrosion.

Addressing these challenges through routine inspections, timely replacements, and proper installation practices keeps your filtration system operating at peak efficiency.

Selecting the Right Industrial Compressed Air Filter

Choosing the appropriate industrial compressed air filter is crucial for system longevity and air quality. Factors to consider include:

Filter media type: glass fiber for fine particles, activated carbon for oil vapor, or sintered metal for durability

Flow rate and pressure ratings: must match the system’s pneumatic requirements

Manufacturer reliability: selecting a reputable compressed air filter manufacturer ensures access to genuine parts and support

Correct selection and installation reduce the likelihood of premature failure and maximize operational efficiency.

Enhancing Air Quality with Scientific Maintenance Practices

Maintaining precision compressed air filters is not merely about replacing cartridges; it is a scientific approach that combines inspection, cleaning, monitoring, and documentation. Key steps include:

Creating a maintenance schedule based on operational hours and air quality metrics

Training operators in proper handling and inspection methods

Keeping detailed records of cartridge replacement, pressure drops, and contaminant levels

This structured approach ensures stable air quality, reduces unexpected downtime, and prolongs the service life of both filters and downstream equipment.

Benefits of Timely Maintenance for Users

Implementing these maintenance strategies provides multiple advantages:

Extended cartridge life, reducing replacement costs

Improved air quality, protecting sensitive pneumatic and production equipment

Lower energy consumption due to optimized airflow

Reduced risk of contamination and production defects

Ultimately, scientific maintenance of precision compressed air filters supports overall productivity, operational safety, and product consistency.

Conclusion

In industrial environments where clean air is a cornerstone of efficiency and quality, the proper maintenance of precision compressed air filters is non-negotiable. Regular cartridge inspection, prompt replacement, detailed monitoring, and thorough cleaning are essential steps for keeping systems reliable and cost-effective. By following these practices, users can ensure that their pneumatic systems operate smoothly, their products meet stringent quality standards, and the filters themselves achieve maximum lifespan.

Investing in maintenance knowledge and adhering to scientific procedures allows facilities to fully leverage the capabilities of compressed air filters, whether for general industrial use or specialized applications in electronics, food, pharmaceuticals, or new energy sectors.

Join us

Join us After-sale service

After-sale service News

News