Ensuring Clean Air Supply with High Pressure Compressed Air Filter

In industries where compressed air is the backbone of production, the importance of filtration cannot be overstated. Contaminants such as oil, dust, water, and solid particles not only damage equipment but also compromise product quality. This is where the high pressure compressed air filter becomes indispensable. Designed to withstand elevated operating pressures while providing superior air purity, these filters are essential for sectors such as pharmaceuticals, food and beverage, petrochemicals, electronics, and heavy manufacturing. In this blog post, as high quality high pressure filter manufacturing factory, Yuanmei will share the features of high pressure compressed air filter for sale, its applications, benefits, etc.

What Is High Pressure Filter for sale?

A high pressure compressed air filter is a specialized filtration device engineered to operate at pressures well beyond standard compressed air systems. While traditional air filters handle pressures up to 16 bar, high pressure filters are designed for ranges between 40 bar and 350 bar, depending on industrial requirements.

The primary role of these filters is to remove aerosols, oil vapors, dust, rust, and condensate before the compressed air reaches critical machinery or processes. With their robust housings, corrosion-resistant materials, and advanced filter media, they ensure reliable performance under demanding conditions.

Need for High Pressure Air Filtration

Compressed air at elevated pressures carries a higher concentration of contaminants due to intensified compression cycles. Without proper filtration, these impurities can:

Cause premature wear on pneumatic tools and actuators.

Lead to product contamination in food or pharmaceutical industries.

Reduce system efficiency due to clogging and corrosion.

Increase maintenance costs and unplanned downtime.

By integrating a compressed air filter for high pressure systems, operators safeguard both equipment longevity and production quality.

Key Features of High Pressure Compressed Air Filter

When evaluating a compressed air high pressure filter, several design elements stand out:

Robust Housing: Constructed from stainless steel, aluminum, or carbon steel with special coatings to endure high pressures.

Multi-Layer Filter Media: Incorporating coalescing elements to remove fine oil aerosols and sub-micron particles.

High Flow Capacity: Engineered to provide maximum filtration efficiency without causing pressure drops.

Drainage Systems: Automatic or manual drains to remove condensed liquid efficiently.

Corrosion Resistance: Ensuring long service life even in harsh environments.

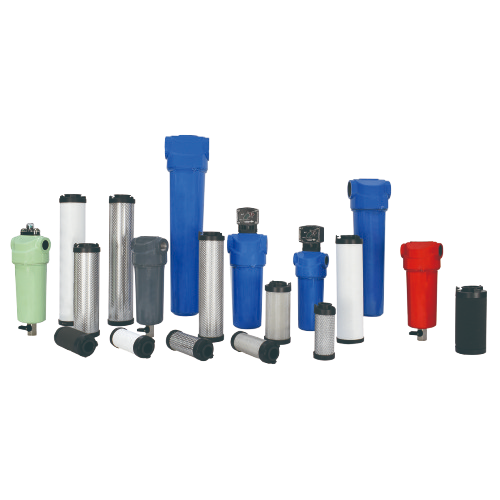

Types of High Pressure Filter Systems

Different industries demand different levels of purity and protection. Common categories include:

Particulate Filters – Remove dust, dirt, and rust particles.

Coalescing Filters – Eliminate oil and water aerosols.

Activated Carbon Filters – Absorb oil vapors, hydrocarbons, and odors.

Sterile Air Filters – Ensure microorganism-free air for pharmaceutical and food production.

By selecting the right industrial high pressure air filter, operators achieve optimal system performance while meeting industry-specific purity standards.

Applications of High Pressure Compressed Air Filters

The use of high pressure compressed air purification systems spans a wide range of industries:

Food & Beverage: Ensuring hygienic, contaminant-free compressed air during packaging and processing.

Pharmaceuticals: Delivering sterile air to safeguard sensitive products.

Oil & Gas: Protecting pneumatic drilling tools and control systems.

Electronics: Preventing particulate contamination in precision manufacturing.

Automotive: Supporting clean air for painting, assembly, and testing processes.

Power Generation: Ensuring turbine controls operate without contamination-induced failures.

Benefits of Using High Pressure Filter

Installing a compressed air filter for high pressure applications delivers long-term advantages:

Improved Air Quality: Ensures compliance with ISO 8573-1 compressed air purity standards.

Reduced Maintenance Costs: Prevents premature wear of valves, actuators, and other pneumatic components.

Extended Equipment Life: Protects against corrosion and mechanical failures.

Operational Efficiency: Minimizes downtime caused by clogged or damaged machinery.

Energy Savings: High-quality filters reduce pressure drop, ensuring efficient system performance.

How to Choose the Right High Pressure Air Filter?

When selecting a high pressure air filter system, several factors must be considered:

Operating Pressure: Verify compatibility with your system’s maximum pressure rating.

Flow Rate: Ensure the filter can handle the volume of compressed air required.

Filtration Grade: Match filter efficiency to the level of purity needed in your industry.

Environmental Conditions: Select corrosion-resistant materials for offshore or chemical applications.

Maintenance Requirements: Look for filters with easy-to-replace elements and reliable drainage systems.

Installation and Maintenance of High Pressure Filters

For maximum efficiency, high pressure compressed air filtration units should be installed at strategic points within the air system:

Before critical equipment: Protecting sensitive machinery.

At the point of use: Ensuring final-stage air quality.

Downstream of compressors and dryers: Removing residual moisture, oil, and particles.

Routine maintenance includes replacing filter elements, checking seals, and monitoring pressure drops. Following the manufacturer’s guidelines ensures prolonged filter life and reliable performance.

Conclusion

The high pressure compressed air filter is more than just an accessory—it is a critical safeguard for industrial operations. By ensuring clean, contaminant-free air, these filters not only enhance equipment reliability but also uphold product quality and regulatory compliance. With proper selection, installation, and maintenance, businesses can significantly reduce operational costs while achieving higher efficiency.

Join us

Join us After-sale service

After-sale service News

News