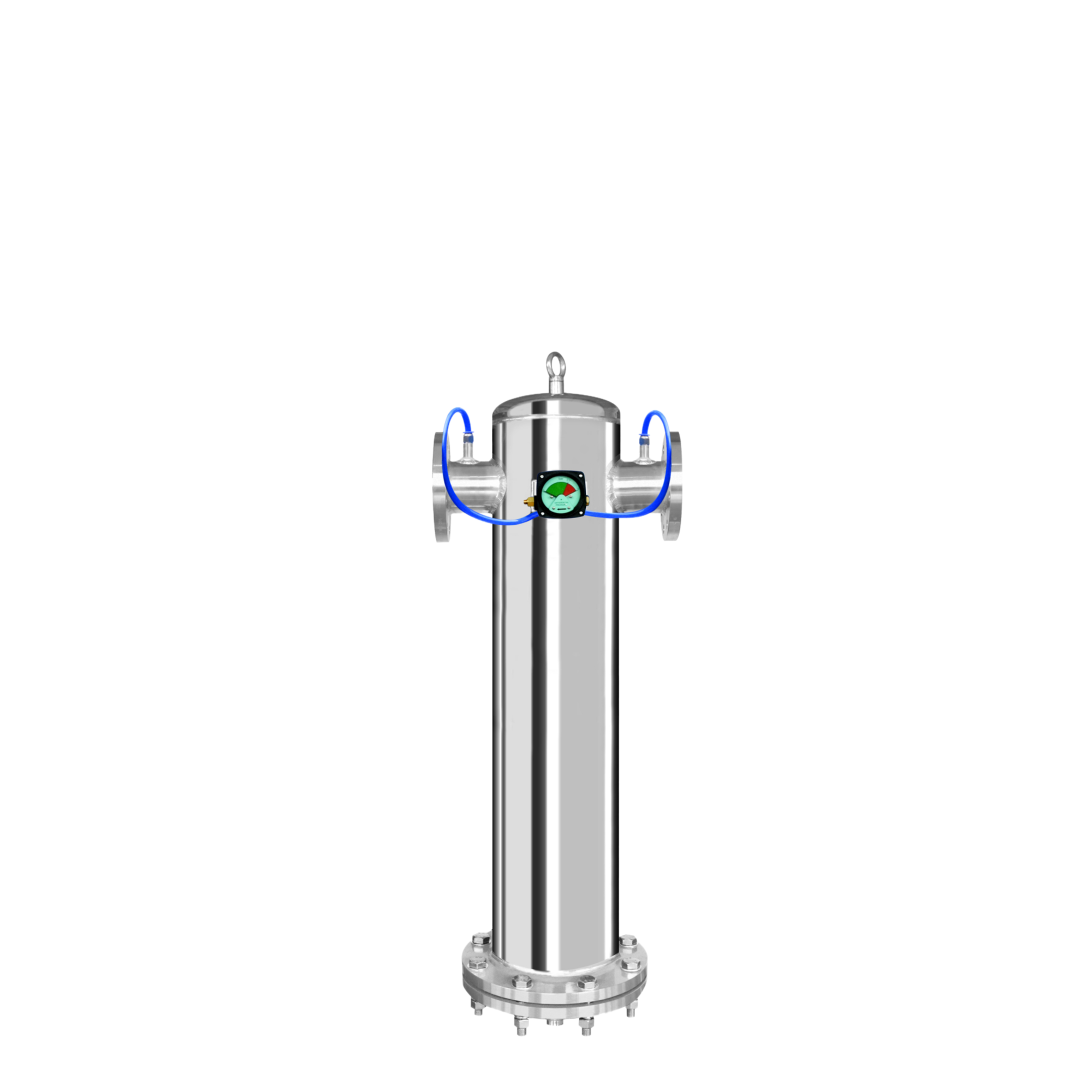

Stainless Steel Flange Compressed Air Filter Built for Precision Industries

Role of Flange Compressed Air Filter in Industry

A flange compressed air filter plays a critical role in ensuring the purity, reliability, and consistency of industrial compressed air systems. As manufacturing environments evolve toward higher precision and more demanding hygienic standards, the quality of compressed air becomes inseparable from the stability of production. From laser processing to pharmaceutical packaging, impurities such as moisture, oil vapors, and solid particulates can cause equipment malfunction, product defects, or even safety risks.

To address these challenges, stainless steel flange-type filtration systems provide an advanced alternative to conventional carbon steel designs. Their corrosion-resistant structure prevents secondary contamination and maintains long-term operational integrity under extreme working conditions. In this blog post, Yuanmei, as one of the high performance air compressor filter manufacturers, will share the structural advantages of flange compressed air filter for sale, etc.

Filtration Accuracy Levels in Stainless Steel Flange Filter

One of the distinguishing features of a premium flanged compressed air filter unit is its graded filtration accuracy. The Yuanmei stainless steel filter series offers multiple precision levels, allowing users to build an efficient multi-stage filtration system that meets ISO 8573-1 purity requirements.

Class C – 3 Micron (Pre Filter)

Designed to remove larger solid particles and bulk contaminants. This stage protects downstream filters and stabilizes system performance.Class T – 1 Micron (After Filter)

Captures smaller particulates and residual moisture, providing cleaner compressed air for general industrial use.Class A – 0.01 Micron (Line Filter)

Suitable for environments requiring extremely low particulate and oil content, often used in combination with precision downstream equipment.Class F – 0.01 Micron (Fine Filter)

Offers enhanced removal of ultrafine contaminants, ideal for precision manufacturing and high-purity applications.Class H – 0.01 Micron (Activated Carbon Filter)

Effective for eliminating oil vapors, odors, and hydrocarbon residues, ensuring odor-free and ultra-clean air for sensitive production lines.

This structured filtration system makes the stainless steel flange filter adaptable to both heavy-duty pre-treatment and ultra-fine point-of-use applications.

Structural Advantages of Stainless Steel Flange Compressed Air Filter

A major reason industries upgrade to stainless steel filtration equipment is the markedly superior durability compared with traditional carbon steel filters. The flange-connected compressed air filter housing delivers multiple structural and operational advantages:

Corrosion-Resistant All-Stainless Construction

The shell, internal frame, and flow-contact components are all made from high-grade stainless steel, preventing rust, oxidation, and contamination. This material integrity is essential for sectors where air purity directly influences product quality, such as food packaging, pharmaceutical mixing, and semiconductor processes.

Secure and Leak-Free Flange Connection

A flange joint offers higher pressure tolerance and greater sealing reliability than threaded connections. The 1.0 MPa-rated stainless steel flange filter withstands long-term continuous operation without the risk of deformation or leakage, making it suitable for harsh operating environments.

Stable Operation Under High Loads

Because stainless steel maintains structural rigidity under temperature fluctuations and vibration, the filter ensures consistent performance even in high-humidity compressor rooms, chemical plants, and outdoor installations.

Prevention of Secondary Pollution

Carbon steel filters are prone to internal rusting, introducing contaminants into the air stream. A stainless steel flanged air purification unit completely eliminates this issue, safeguarding the integrity of downstream machinery like robotic sprayers, CNC machines, and laser cutters.

Applications of Flange Compressed Air Filter Across Industries

The versatility of a flange-mounted compressed air filtration system comes from its ability to meet diverse purity requirements across industrial sectors. Typical applications include:

Food and Beverage Production

In this sector, compressed air may come into direct or indirect contact with ingredients, packaging materials, or bottling processes. Stainless steel filters prevent rust particles or vapor contamination, supporting HACCP compliance and hygienic production.

Pharmaceutical and Biotechnology Manufacturing

High-purity compressed air is essential for tablet coating, fermentation, sterile packaging, and pneumatic conveying. The multi-grade filtration stages ensure that microbial, particulate, and hydrocarbon contaminants remain within strict regulatory limits.

Electronic and Semiconductor Fabrication

Even trace contaminants can destroy delicate wafers or disrupt controlled environments. Class A, F, and H corrosion-resistant flange filters contribute to low-particle, low-oil compressed air essential for precision circuitry and micro-component production.

Chemical and Petrochemical Operations

Chemically aggressive environments demand a filtration solution immune to corrosion. Stainless steel construction resists acid vapors, solvents, and oxidizing conditions while ensuring long-term, stable operation.

Automotive and Precision Engineering

Painting systems, laser cutting heads, pneumatic actuators, and robotic arms all depend on clean, dry, and stable airflow. The flange compressed air filter supports continuous high-precision output and protects valuable equipment from premature wear.

Why Stainless Steel Flange Filters Excel in Harsh Working Conditions

In addition to material advantages, the system design provides operational reliability unmatched by traditional filter housings. A well-engineered industrial flange compressed air filter exhibits:

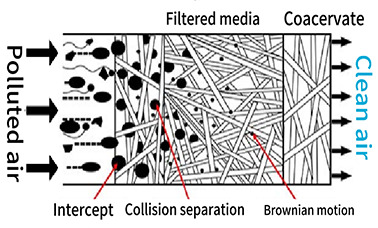

Consistent Airflow Distribution

Internal flow paths are designed for reduced turbulence, lower pressure drop, and balanced airflow. This ensures efficient contaminant capture across all grades of filter elements.

Durability Under Mechanical Stress

Stainless steel maintains its performance under thermal cycling, mechanical shocks, and continuous vibrations—common challenges in chemical plants, compressor stations, and factory floors.

Easy Maintenance and Long Service Life

The flange design simplifies disassembly for inspection and filter replacement. Combined with corrosion resistance, this extends the filter’s life cycle, reduces downtime, and minimizes maintenance costs.

Compatibility With International Standards

These filters meet CE, ISO, and ISO 8573-1 requirements, making them suitable for regulated industries and international export markets. Buyers gain confidence knowing that the filtration system meets globally recognized safety and quality benchmarks.

Technical Value of Multi-Grade Filter Elements in Flange System

While the stainless steel housing provides durability, the true purification performance comes from the internal filter elements. Each filtration class is engineered for specific requirements:

Pre-filters reduce the load on finer elements and extend their service life.

After-filters support general equipment protection.

Line and fine filters ensure high-purity compressed air for precision tasks.

Activated carbon filters provide odor control and hydrocarbon adsorption for sensitive equipment.

This modular approach allows operators to tailor their flange air filtration setup based on the purity level required for each segment of the production process.

Meeting the Demands of High-Standard Production Environments

As industries adopt smart manufacturing, digitalized quality control, and automated workflows, the expectations for compressed air purity have risen sharply. Stainless steel flange compressed air filters align with these requirements by delivering:

Reliable Quality for High-Value Equipment

Laser cutting systems, robotic sprayers, and optical instruments depend on ultra-clean air. Any contamination could reduce precision or damage costly tools.

Stable Purity for Consistent Product Output

Whether producing beverages, pharmaceuticals, or electronic components, manufacturers need stable air purity to maintain batch consistency and reduce defects.

Reduced Risk of Cross-Contamination

In multi-product facilities, maintaining air purity prevents contamination from one production line affecting another.

Compliance With Strict Global Standards

Industries expanding internationally require equipment that meets regulatory expectations across different regions. Stainless steel flange filters provide this assurance.

Conclusion

The stainless steel flange compressed air filter offers a powerful combination of corrosion-resistant construction, refined filtration precision, multi-stage contaminant control, and structural durability. By adopting flange-mounted stainless steel filters, enterprises gain a dependable air purification system capable of supporting demanding industrial processes and maintaining product integrity.

From pharmaceuticals to electronics and food processing, the ability to deliver clean, stable, and standards-compliant compressed air is essential. Stainless steel flange filtration systems are therefore not just equipment choices—they are strategic investments that protect production, extend equipment life, and uphold industry quality standards.

Join us

Join us After-sale service

After-sale service News

News