Stainless Steel Compressed Air Filter Solutions for Critical Industries

Why Stainless Steel Compressed Air Filters Are Essential

In modern industrial environments, the purity of compressed air directly influences production quality, operational safety, and equipment longevity. A stainless steel compressed air filter provides unmatched durability and filtration efficiency compared with conventional carbon steel or plastic alternatives. By combining corrosion resistance with high filtration precision, these filters are particularly valuable in industries where hygiene and contamination control are paramount. In this blog post, Yuanmei, a high performance custom made air filters exporter, will share the advantages of stainless steel compressed air filter for sale, its applications, etc.

Advanced Filtration Classes for Different Applications

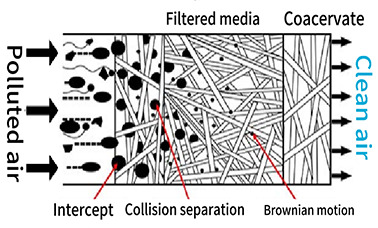

The filtration capacity of a stainless steel air purifier for compressed systems is categorized by precision levels. Each class is designed to remove specific contaminants from the airflow:

Class C (3 Micron, Pre Filter): Removes larger particles such as dust and rust, protecting downstream filters.

Class T (1 Micron, After Filter): Captures finer particles to prepare air for sensitive processes.

Class A (0.01 Micron, Line Filter): Eliminates nearly all oil mist, water vapor, and microorganisms.

Class F (0.01 Micron, Fine Filter): Provides ultra-clean compressed air for high-standard production lines.

Class H (0.01 Micron, Activated Carbon Filter): Specially designed to remove oil vapors and odors, ensuring air purity for food and pharmaceutical environments.

This multi-stage approach ensures that businesses can tailor their filtration system to meet both ISO 8573-1 standards and their unique operational requirements.

Superior Filtration with Micron-Level Precision

The industrial stainless steel compressed air filter is engineered to separate and remove oil aerosols, liquid water, and microscopic particles. With filtration accuracy down to 0.01 μm, these units guarantee clean, dry air for even the most demanding applications. Whether protecting sensitive electronics in semiconductor production or ensuring sterile conditions in pharmaceutical lines, these filters play a vital role in safeguarding processes.

Corrosion Resistance Through All-Stainless Construction

One of the most defining features of a 304/316 stainless steel filter housing for compressed air is its robust construction. Unlike carbon steel, which can corrode and introduce secondary contamination, stainless steel offers:

Resistance to rust and chemical corrosion

Mechanical strength for high-pressure systems

Extended service life, even in humid or chemically aggressive environments

This makes stainless steel compressed air filters the preferred choice for industries where contamination control cannot be compromised, such as dairy processing, injectable drug production, and electronics assembly.

Energy Efficiency and Low Pressure Drop Design

Compressed air is one of the most expensive utilities in industrial facilities. A poorly designed filter can cause high pressure drops, forcing compressors to consume more energy. The low pressure drop compressed air filter design minimizes resistance within the housing, offering:

Reduced compressor energy consumption

Lower operating costs

Consistent air supply without fluctuations

This combination of performance and efficiency delivers both sustainability benefits and measurable financial savings.

Simplified Maintenance with Modular Design

Time is money in industrial operations. The stainless steel modular compressed air filter incorporates a quick-release cover mechanism that allows filter elements to be replaced in less than a minute—without specialized tools. This minimizes downtime, reduces labor costs, and ensures reliable operation with minimal disruption.

Protecting Sensitive Equipment and Final Products

Compressed air contamination can lead to costly damage. Laser cutting heads, spraying equipment, and precision measurement instruments are highly vulnerable to oil mist or fine particulate contamination. By deploying a high-performance stainless steel compressed air filter, manufacturers prevent secondary damage and extend the lifespan of expensive equipment. Moreover, clean air ensures that end products—whether food, medicine, or microchips—meet strict quality and safety requirements.

Meeting International Standards and Certifications

Professional suppliers of sanitary stainless steel compressed air filters design products that comply with stringent global benchmarks. Certifications such as CE and ISO, along with adherence to ISO 8573-1 air quality standards, guarantee reliability and regulatory compliance. These credentials are particularly vital in industries with strict audits and hygiene standards, including pharmaceuticals and food & beverage production.

Applications Across High-Demand Sectors

The versatility of a stainless steel inline air filter for compressors makes it suitable for diverse industries:

Food & Beverage: Prevents oil, water, or rust contamination in bottling, brewing, and dairy processing.

Pharmaceutical Manufacturing: Provides sterile, contaminant-free air essential for drug formulation and packaging.

Electronics & Semiconductors: Protects delicate circuit boards and wafers from microscopic dust and vapor.

Chemical Processing: Ensures chemical purity and prevents reactions triggered by contaminated air.

Laser Cutting & Robotics: Maintains precision and protects sensitive nozzles and robotic actuators.

Long-Term Value of Stainless Steel Air Filtration

While the initial investment in a premium stainless steel compressed air filter system may be higher than that of aluminum or carbon steel models, the long-term advantages are clear. With extended service life, reduced maintenance requirements, and energy savings, these filters provide an excellent return on investment. Most importantly, they deliver peace of mind by ensuring product integrity and operational reliability.

Conclusion

In industries where the cost of air contamination is measured not only in financial losses but also in safety risks and product recalls, stainless steel compressed air filters stand as the most reliable solution. Their precision filtration, corrosion resistance, energy efficiency, and easy maintenance make them indispensable across sectors. Choosing a high-performance stainless steel air filtration system is not just a technical decision—it is a strategic investment in long-term quality, efficiency, and compliance.

Join us

Join us After-sale service

After-sale service News

News