How to Extend the Service Life of High Pressure Compressed Air Filters?

High pressure compressed air filters play a critical role in industrial pneumatic systems, protecting downstream equipment, ensuring air purity, and stabilizing production quality. However, in many facilities, filter cartridges are replaced far more frequently than expected, leading to higher operating costs, increased downtime, and inconsistent system performance.

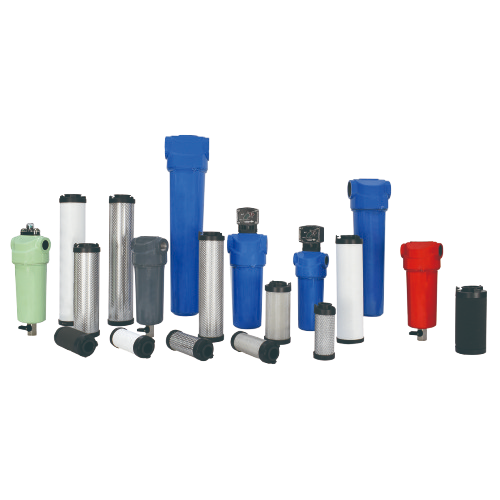

Extending the service life of a high pressure compressed air filter is not solely dependent on the cartridge itself. Instead, it is the result of a systematic approach, involving inlet air management, filtration configuration, operating conditions, maintenance discipline, and correct installation practices. Understanding how these factors interact allows engineers and maintenance teams to maximize filtration efficiency while minimizing unnecessary cartridge consumption. In this blog post, YUANMEI, as one of the high quality industrial compressed air filter manufacturers, will share how to extend the service life of high pressure compressed air filters.

Understanding the Working Environment of High Pressure Compressed Air Filters

A high pressure compressed air filter operates under conditions that are inherently more demanding than standard air filtration systems. Elevated pressure intensifies airflow velocity, particle impact force, and contaminant penetration depth. As pressure increases, even small design or operational deficiencies can significantly reduce cartridge lifespan.

In typical industrial environments, compressed air contains a mixture of solid particles, oil aerosols, water vapor, and occasionally corrosive gases. Under high pressure, these contaminants are driven deeper into the filter media, accelerating blockage and material fatigue. Therefore, extending service life begins with understanding the true contamination load entering the filter system rather than relying solely on nominal specifications.

Common Causes of Frequent Replacement in High Pressure Compressed Air Filter Systems

Premature cartridge failure is rarely accidental. In most cases, it can be traced back to one or more recurring system-level issues.

Poor Inlet Air Quality Before the High Pressure Filter

When excessive dust, suspended particles, or oil mist enter the compressed air system, the high pressure compressed air filter becomes overloaded in a short time. Fine particles embed rapidly into the filter media, increasing pressure drop and reducing effective filtration area.

Oil aerosols are particularly damaging, as they bind dust into sticky agglomerates that block pores and prevent uniform airflow distribution. Once oil contamination occurs, cleaning becomes ineffective, and cartridge replacement is unavoidable.

Inappropriate or Missing Pre-Filtration Stages

Many systems rely solely on a single high pressure compressed air filter to perform all filtration tasks. Without effective pre-filtration, large particles and bulk contaminants directly impact the precision filter media, dramatically reducing dirt-holding capacity.

A lack of matched coarse or medium-efficiency filters upstream forces the high pressure filter to function beyond its intended role, leading to rapid clogging and uneven media loading.

Low-Quality Filter Cartridges in High Pressure Applications

Inferior cartridges often suffer from inconsistent fiber distribution, limited dirt-holding capacity, and weak structural integrity. Under high pressure conditions, these weaknesses become more pronounced.

Uneven pore size leads to localized blockage, while insufficient mechanical strength may cause deformation or internal collapse. As a result, pressure drop increases sharply, and filtration efficiency becomes unstable long before the expected service interval.

Abnormal Operating Conditions Affecting Filter Media

Environmental factors such as high humidity, frequent temperature fluctuations, or the presence of corrosive gases accelerate degradation of filter materials. Moisture promotes particle adhesion and microbial growth, while temperature cycling can weaken bonding agents within the filter media.

In high pressure compressed air filter systems, these effects compound faster, as pressure amplifies stress on the cartridge structure and sealing components.

Optimizing Inlet Air Pretreatment for High Pressure Compressed Air Filters

One of the most effective ways to extend cartridge life is to reduce the contaminant load before it reaches the high pressure filter.

Installing properly matched coarse and medium-efficiency pre-filters allows larger particles to be intercepted early. This staged approach ensures that each filtration level handles contaminants within its optimal range, preventing premature saturation of the precision cartridge.

Regular inspection and timely replacement of pre-filters are equally important. A clogged pre-filter increases upstream turbulence, forcing contaminants through unintended pathways and undermining the performance of the high pressure compressed air filter.

Managing the Operating Environment to Reduce Cartridge Stress

The physical location of the air intake has a direct impact on filter longevity. Intakes positioned near dust sources, oil fumes, or humid zones introduce unnecessary contamination into the system.

Relocating intake points, installing protective intake housings, or adding localized air cleaning solutions can significantly improve inlet air quality. In environments with persistent moisture or oil vapor, dehumidifiers and oil separators become essential companions to the high pressure compressed air filter.

By stabilizing environmental conditions, the filter cartridge experiences more uniform loading, reducing localized blockage and extending usable service time.

Selecting High-Quality Cartridges for High Pressure Compressed Air Filtration

Not all filter cartridges are designed to perform reliably under high pressure. Selecting cartridges with a gradient pore structure is particularly important in demanding applications.

Gradient filtration allows particles of different sizes to be captured progressively across multiple layers, rather than accumulating on a single surface. This layered capture mechanism increases dirt-holding capacity, maintains stable pressure drop growth, and delays the onset of critical blockage.

High-quality cartridges also feature reinforced cores, stable end caps, and materials resistant to moisture and chemical exposure. While the initial cost may be higher, the extended service life and reduced downtime often result in lower total operating costs.

Monitoring Differential Pressure to Optimize Replacement Timing

Relying on fixed replacement intervals often leads to unnecessary cartridge changes or, conversely, delayed replacement that risks system damage. Differential pressure monitoring provides a data-driven approach to maintenance decisions.

As contaminants accumulate, pressure drop across the high pressure compressed air filter increases gradually. Monitoring this trend allows maintenance teams to identify abnormal loading patterns, potential upstream issues, or improper operating conditions.

When pressure difference begins to rise slightly above baseline, controlled surface cleaning—such as reverse compressed air blowing—may be performed if permitted by the manufacturer. However, once the maximum allowable pressure difference is reached, prompt replacement is essential to protect downstream equipment and maintain air quality.

Proper Cleaning Practices for Extended Filter Performance

Cleaning must be performed carefully to avoid damaging the filter media. Excessive air pressure, improper direction, or aggressive mechanical contact can rupture fibers and compromise filtration efficiency.

For high pressure compressed air filter cartridges designed for cleaning, reverse airflow at controlled pressure helps dislodge surface particles without forcing contaminants deeper into the media. Cleaning should be viewed as a life-extension measure, not a substitute for replacement beyond design limits.

Following manufacturer guidelines ensures that cleaning extends service life without sacrificing performance or safety.

Ensuring Correct Installation to Prevent Premature Contamination

Even the highest-quality cartridge will fail prematurely if installed incorrectly. Deformation during installation or improper sealing allows unfiltered air to bypass the media, depositing contaminants unevenly and accelerating blockage.

Careful alignment, correct torque on housing components, and inspection of sealing surfaces are essential steps. After installation, verifying pressure stability and checking for leakage confirms that the high pressure compressed air filter is operating as intended.

Proper installation not only protects the cartridge but also ensures consistent air quality throughout the compressed air system.

Building System-Level Strategy for High Pressure Compressed Air Filter Longevity

Extending the service life of a high pressure compressed air filter is not achieved through a single action. It requires coordination across system design, environmental control, component selection, and maintenance planning.

By improving inlet air quality, implementing staged filtration, selecting robust cartridges, monitoring differential pressure, and enforcing proper installation procedures, facilities can significantly reduce replacement frequency. The result is a more reliable compressed air system, lower operating costs, and improved production stability.

In high pressure applications, where filtration demands are intensified, adopting a holistic approach transforms the filter from a consumable expense into a controlled, optimized component of the overall system.

Join us

Join us After-sale service

After-sale service News

News