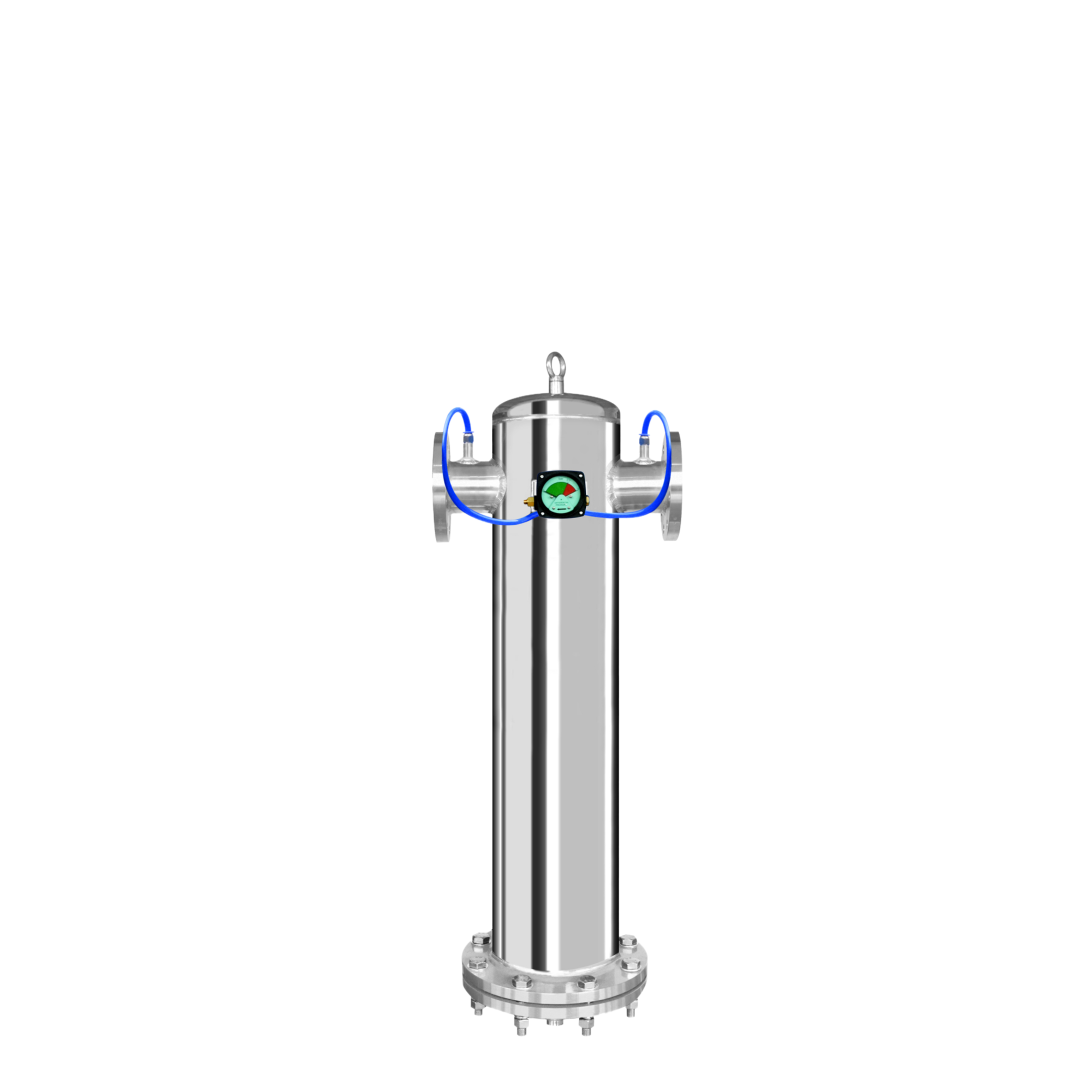

ACF Compressed Air Filter Solutions for Industrial Purification Needs

Compressed air is a critical utility in modern industrial operations, but its quality directly affects equipment efficiency, product integrity, and overall operational safety. The ACF filter series offers a comprehensive solution for achieving clean, dry, and oil-free air in demanding environments. In this blog post, Yuanmei, as high performance custom industrial air filters manufacturer, will share the advantages of ACF compressed air filters for sale, its features, applications, etc.

Key Advantages of ACF Filter

The ACF compressed air filter series is designed with both performance and durability in mind. By combining high-quality materials, patented designs, and precision manufacturing, these filters offer several key advantages:

Superior Filtration Efficiency – The ACF Series covers multiple filtration classes, from Class C to Class H, providing filtration for particles as small as 0.01μm and ultra-low oil content levels down to 0.001ppm. This ensures reliable protection for sensitive machinery and production processes.

High-Pressure Resistance – Constructed from aerospace-grade silicon-aluminum alloy and precision die-cast, the ACF filter housing withstands extreme conditions, including operating pressures up to 16 bar and ultra-high-pressure tests up to 4.0 MPa. This structural integrity minimizes leakage risks and extends service life.

Advanced Anti-Corrosion Protection – The housing benefits from multi-step surface treatment, including degreasing, passivation, internal electrophoretic coating, and electrostatic powder coating. This multi-layer system ensures long-term durability, even in harsh industrial environments with high humidity or chemical exposure.

Innovative Industrial Design – Beyond functional excellence, the ACF Series showcases a minimal yet elegant industrial design. Patented filter element interfaces and drainage structures improve maintainability, while the aesthetic design complements modern industrial layouts.

Versatility Across Filtration Needs – With various classes available, these filters can handle everything from general water and oil mist removal to ultra-efficient oil vapor elimination. This versatility allows industrial operators to select the right filter type according to system requirements.

Core Features of Precision ACF Filter

The ACF Series integrates advanced technologies that ensure performance, reliability, and longevity:

Patented Filter Element Interface – Independent research and development have yielded a unique filter element interface, providing superior sealing performance and simplifying maintenance operations.

Cyclone and Coagulation Separation – Depending on the filter class, ACF compressed air filters utilize cyclone separation, collision separation, and coagulation filtration techniques to capture particles efficiently, ensuring clean and dry air.

Multi-Layer Protection Housing – Precision die-cast aluminum alloy housings undergo deep cleaning, degreasing, passivation, electrophoretic anti-corrosion coating, and high-strength epoxy powder coating. This combination resists corrosion, mechanical wear, and high-pressure conditions.

High-Precision Filter Media – Designed to capture particles down to 0.01μm, the filter media ensures ultra-fine purification while maintaining high airflow rates and minimal pressure drops.

Comprehensive Class Options – The ACF Series is categorized into Class C, T, A, F, and H filters, each tailored for specific industrial applications and purification requirements.

ACF Filter Classes and Their Industrial Applications

Understanding the specific classes of ACF compressed air filters is crucial for selecting the right solution:

Class C – General Particle Removal

Class C filters employ efficient cyclone and collision separation to remove particles larger than 3μm. They are suitable for pre-filtration in systems where moderate oil content (≤ 5ppm) is acceptable. Typical applications include air-driven tools, pneumatic systems, and general industrial equipment.

Class T – Main Pipeline Filtration

Class T filters focus on coagulation-based main pipeline filtration, capturing particles ≥ 1μm and reducing oil content to ≤ 1ppm. They are ideal for systems where equipment protection and air quality are critical, such as manufacturing lines, packaging systems, and processing plants.

Class A – Efficient Oil Removal

Class A filters use coagulation techniques to achieve high-efficiency oil and water removal. Particles down to 0.01μm are captured, and oil content is reduced to ≤ 0.01ppm. These filters are commonly used in food, pharmaceutical, and electronics industries where air purity directly affects product quality.

Class F – Ultra-Efficient Oil Removal

Class F filters provide ultra-efficient oil removal, with filtration of particles ≥ 0.01μm and oil content ≤ 0.001ppm. Applications include precision machinery, high-tech manufacturing, and laboratories where even trace oil contamination can compromise processes.

Class H – Activated Carbon for Oil Vapor

Class H filters incorporate activated carbon to remove oil vapors and odors, capturing solid particles above 0.01μm. The remaining oil vapor is limited to 0.003ppm at 21℃, making these filters suitable for sensitive environments such as cleanrooms, pharmaceutical production, and electronics fabrication.

Diverse Applications of ACF Compressed Air Filter

The versatility of the ACF compressed air filter series allows it to serve a wide range of industrial environments:

Manufacturing and Automation – Protects CNC machines, robotic systems, and production lines from contamination that could lead to equipment wear and downtime.

Food and Beverage Industry – Ensures that compressed air used in packaging and processing is free of oil, water, and particulates, maintaining hygiene and safety standards.

Pharmaceutical and Biotechnology – Provides ultra-clean air for sensitive processes where particle and oil contamination can compromise product integrity.

Electronics and Semiconductor Production – Maintains high air purity to prevent defects in delicate electronic components.

Automotive and Aerospace – Supports painting, coating, and pneumatic systems that require consistent, oil-free air to maintain surface quality and equipment longevity.

Laboratories and Cleanrooms – Class H activated carbon filters deliver ultra-pure air for precise testing, chemical handling, and research applications.

User Value and Benefits of ACF Compressed Air Filter

Choosing ACF compressed air filters offers tangible benefits for industrial operators:

Reduced Maintenance Costs – High durability and robust construction minimize filter replacements, maintenance downtime, and associated labor costs.

Enhanced Equipment Lifespan – Efficient particle and oil removal reduces wear on pneumatic tools, compressors, and downstream equipment, prolonging service life.

Consistent Product Quality – Ultra-pure compressed air ensures production processes remain stable, reducing defects and improving end-product quality.

Operational Safety – Reliable sealing and high-pressure resistance prevent leaks and potential hazards, maintaining safe working conditions.

Flexibility and Scalability – Multiple filter classes and modular design allow easy customization for different industrial setups and future expansion.

Environmental Compliance – By minimizing oil discharge and contaminant release, ACF compressed air filters help industries meet environmental standards and reduce ecological impact.

Conclusion

The ACF compressed air filter series by Yuanmei Filtration represents a benchmark in industrial air purification technology. Combining innovative designs, multi-layered protection, and superior filtration efficiency, the series addresses the diverse needs of modern industries. Whether it’s general particle removal, ultra-fine oil elimination, or activated carbon vapor purification, ACF filters provide reliable, long-lasting, and visually refined solutions. Industrial operators benefit from cleaner air, reduced maintenance, and enhanced equipment performance, making these filters an essential component in maintaining efficiency, safety, and product quality across sectors.

Join us

Join us After-sale service

After-sale service News

News