Precision Air Filter Solutions for Compressed Air Systems

Compressed air quality directly affects equipment reliability, product integrity, and operational safety. In industrial environments where even microscopic contaminants can lead to corrosion, wear, or process failure, the Precision Air Filter plays a decisive role. At the heart of these filtration systems are precision air filter cartridges, engineered to remove fine particles, aerosols, and other impurities from gas media before they reach downstream equipment.

In this blog post, as high quality custom industrial air filter factory, Yuanmei will share an overview of precision air filters for sale and introduce the manufacturing processes for wound and pleated filter elements. By examining their structures, filtration mechanisms, and application scenarios, readers can better understand how to select appropriate solutions for different compressed air requirements.

Introduction to Precision Air Filter Cartridges

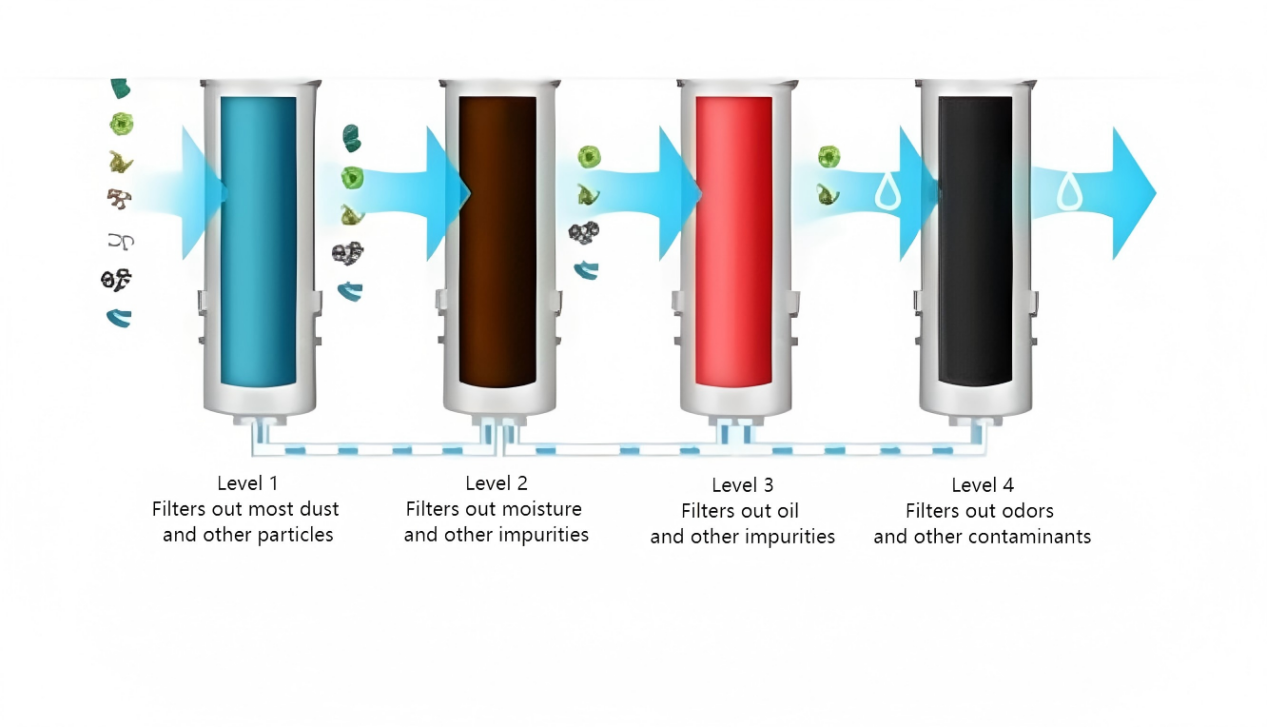

Precision air filter cartridges are the core functional elements of air filtration systems. Designed for raw material treatment and resource recycling, these cartridges enable the effective separation of contaminants from gaseous media. In compressed air applications, their primary task is to remove trace impurities such as dust, rust particles, oil mist, and other suspended solids.

When compressed air flows through a precision filter cartridge, impurities are intercepted by the filtration medium through mechanisms such as surface interception, depth filtration, and inertial impaction. Clean air then exits the cartridge and proceeds to downstream equipment, ensuring system cleanliness and stable performance.

A well-designed precision air filtration cartridge not only improves air quality but also extends the service life of pneumatic tools, valves, and instruments. As industrial standards for air purity become more stringent, the demand for high-efficiency precision air filter solutions continues to grow.

Structural Principles of Precision Air Filter Media

The performance of a precision air filter largely depends on the structure and material of its filtration media. Regardless of cartridge type, several core principles apply:

Controlled pore structure to capture particles within a defined micron range

Mechanical strength to withstand pressure fluctuations

Chemical compatibility with oil vapor, moisture, and process gases

Stable airflow characteristics to minimize pressure drop

Different manufacturing processes address these requirements in different ways. Wire wound and pleated precision air filter cartridges represent two distinct but complementary approaches to achieving reliable air purification.

Wire Wound Precision Air Filter Cartridges and Their Filtration Mechanism

Wire wound precision air filter cartridges are produced by tightly winding textile yarns—such as polypropylene, acrylic fiber, or absorbent cotton—around a porous central core. The winding process is carefully controlled to create a gradient density structure from the outer layer to the inner layer.

This design enables effective depth filtration, where contaminants of varying sizes are trapped at different depths within the cartridge. Larger particles are intercepted on the outer layers, while finer particles are captured deeper inside the winding structure.

Key characteristics of wire wound precision air filtration cartridges include:

Adjustable filtration accuracy through winding density and yarn thickness

High dirt-holding capacity, suitable for air streams with higher particulate loads

Uniform flow distribution, reducing localized clogging

Because of their structural robustness, wire wound cartridges are often used as pre-filtration or intermediate filtration elements within a multi-stage precision air filter system.

Materials Used in Wire Wound Air Filter Cartridges

Material selection is critical in determining the compatibility and performance of wire wound precision air filters. Commonly used yarn materials include:

Polypropylene fibers, offering good chemical resistance and low moisture absorption

Acrylic fibers, suitable for moderate temperature environments

Absorbent cotton, effective for capturing fine particulates in dry air systems

The central core, typically made from polypropylene or stainless steel, provides mechanical support and ensures stable airflow under operating pressure. This combination of materials allows wire wound precision air filter cartridges to operate reliably across a wide range of industrial conditions.

Typical Applications of Wire Wound Precision Air Filters

Wire wound cartridges are widely applied in scenarios where compressed air contains relatively high levels of solid contaminants. Typical uses include:

Pre-filtration stages in compressed air treatment units

Protection of downstream high-precision air filters

General industrial air systems with fluctuating particle loads

Their ability to handle higher contamination levels makes them a cost-effective component in comprehensive precision air filtration strategies.

Pleated Precision Air Filter Cartridges and Advanced Filtration Design

Pleated precision air filter cartridges represent a more advanced filtration technology, designed to achieve higher efficiency within a compact form factor. These cartridges utilize high-performance filtration media such as polypropylene melt-blown membranes, nylon microporous membranes, or PTFE membranes.

The pleated structure significantly increases the effective filtration area without increasing cartridge size. This design allows pleated precision air filters to achieve fine filtration ratings—typically ranging from 0.1 μm to 60 μm—while maintaining low pressure drop.

As compressed air passes through the pleated media, contaminants are primarily captured on or near the surface of the membrane. This surface filtration mechanism enables precise particle retention and predictable filtration performance.

Structural Features of Pleated Precision Air Filter Elements

Pleated precision air filter cartridges are engineered with attention to both performance and installation compatibility. Key structural features include:

Thermally bonded end caps, ensuring leak-free sealing

Uniform pleat spacing, maintaining consistent airflow distribution

Standardized connector options, such as 222, 226, and flat seals

The use of thermal bonding, rather than adhesives, enhances chemical stability and prevents contamination caused by bonding agents. Before delivery, each pleated precision air filter element typically undergoes integrity testing to verify filtration efficiency and structural reliability.

Filtration Accuracy and Efficiency of Pleated Air Filters

One of the defining advantages of pleated precision air filters is their ability to achieve high filtration accuracy with stable airflow characteristics. Fine membrane structures enable consistent particle retention across the entire surface area, reducing the risk of bypass or uneven loading.

This makes pleated cartridges particularly suitable for applications requiring strict air quality control, such as:

Instrument air systems

Food and beverage processing

Pharmaceutical and electronics manufacturing

In these environments, pleated precision air filter cartridges often serve as final filtration stages, ensuring compliance with cleanliness standards.

Comparing Wire Wound and Pleated Precision Air Filter Technologies

While both cartridge types are essential components of precision air filtration systems, their roles differ based on performance characteristics:

Wire wound precision air filters emphasize depth filtration and high dirt-holding capacity

Pleated precision air filters focus on fine filtration accuracy and compact design

In practice, many compressed air systems combine both technologies. Wire wound cartridges may be installed upstream to reduce particulate load, while pleated cartridges provide final polishing filtration.

Selection Considerations for Precision Air Filter Cartridges

Choosing the appropriate precision air filter cartridge requires careful evaluation of operating conditions, including:

Required air purity level

Particle size distribution

System pressure and temperature

Maintenance intervals and cost considerations

Understanding the strengths of different cartridge processes allows system designers to optimize filtration performance while maintaining operational efficiency.

Conclusion

Precision air filter cartridges are indispensable for ensuring clean and reliable compressed air in modern industrial systems. Wire wound and pleated cartridge technologies each offer distinct advantages, addressing different stages and requirements within air filtration processes.

By applying the appropriate cartridge type based on contamination levels and performance expectations, operators can achieve stable air quality, protect downstream equipment, and support long-term system reliability. As industrial demands continue to evolve, well-engineered precision air filter solutions will remain a cornerstone of efficient compressed air treatment.

Join us

Join us After-sale service

After-sale service News

News