Three Factors That Ultimately Decide Compressed Air Precision Filter Efficiency

In industrial compressed air systems, precision filters are rarely the most expensive components, yet they are often the most misunderstood. Many performance complaints—unexpected contamination, unstable air quality, shortened equipment life—are not caused by defective filters, but by deeper mismatches between filtration design, operating conditions, and maintenance discipline.

In this blog post, Wuxi Yuanmei, as high quality compressed air filtration solutions exporter, will share three factors that ultimately decide compressed air precision filter efficiency.

Filter Element Performance Parameters Define the Upper Limit of Filtration Efficiency

Every compressed air precision filter has a theoretical efficiency ceiling, and that ceiling is set by the filter element itself. Once the wrong parameters are chosen, no amount of downstream control can compensate for the loss.

Filter Media Selection Directly Shapes Contaminant Capture Behavior

Different filter media interact with contaminants in fundamentally different ways. Hydrophobic PTFE membranes, borosilicate glass fiber layers, and activated carbon structures are not interchangeable, even when labeled with the same nominal filtration rating.

PTFE membranes excel at resisting moisture penetration and oil mist coalescence, but their performance depends heavily on membrane integrity and folding density. Glass fiber elements offer excellent depth filtration and high dirt-holding capacity, yet their efficiency can degrade under excessive humidity. Activated carbon elements, often misunderstood, are highly sensitive to temperature and saturation and should never be treated as general-purpose particulate filters.

Choosing media based solely on micron rating ignores how oil aerosols, condensed water, and fine solids behave together in real compressed air streams.

Effective Filtration Area Determines Stability, Not Just Capacity

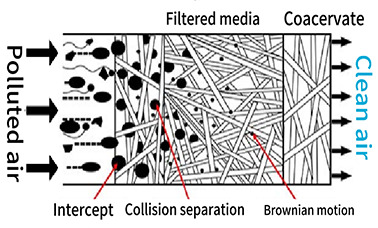

Filtration efficiency is not only about how small a particle a filter can stop, but how consistently it can do so over time. A larger effective filtration area—achieved through optimized pleat geometry and layer distribution—reduces face velocity, improves contaminant capture probability, and slows pressure differential growth.

When filters with insufficient effective area are pushed close to their flow limits, contaminants are more likely to pass through due to reduced residence time. This phenomenon often explains why “new” filters fail to deliver expected air purity shortly after installation.

Precision Matching Matters More Than Absolute Accuracy

One of the most common efficiency failures occurs when filter precision does not align with actual air quality requirements. Installing a 3 μm pre-filter in applications requiring 0.01 μm oil aerosol control is not a minor oversight—it guarantees downstream contamination.

Equally problematic is excessive precision at the wrong stage. Ultra-fine filter elements placed too early in the filtration train will clog rapidly, lose efficiency, and introduce unstable pressure behavior. Filtration efficiency depends on precision sequencing, not individual filter accuracy.

Aging and Structural Fatigue Cause Invisible Efficiency Loss

Filter elements rarely fail catastrophically. Instead, efficiency erodes gradually through fiber fatigue, pore deformation, and micro-damage caused by pressure pulsation. Over time, contaminants no longer accumulate uniformly but begin to penetrate weakened regions, leading to localized breakthrough.

This explains why air quality can degrade even when pressure drop appears acceptable. Filtration efficiency loss is often structural, not hydraulic.

Operating Conditions Redefine How Efficient Precision Filter Can Be

Even a perfectly specified filter element cannot maintain its rated efficiency if operating conditions push it outside its design envelope. Compressed air is a dynamic medium, and its properties directly affect contaminant behavior.

Temperature and Humidity Alter Contaminant Physics

High operating temperatures reduce oil viscosity and increase aerosol mobility, making fine oil droplets harder to capture. At the same time, adsorption efficiency in carbon-based elements declines sharply with heat.

Humidity introduces a different challenge. As compressed air cools, water vapor condenses into microdroplets that act as contaminant carriers. These droplets can transport fine solids and oil through filter media not designed for liquid-phase separation. Persistent moisture also accelerates microbial growth inside the filter housing, introducing secondary contamination that no filter rating accounts for.

Pressure Stability Is a Hidden Efficiency Variable

Precision filters are designed to operate within specific pressure ranges. Sudden pressure fluctuations can deform filter media, compromise sealing surfaces, and create internal bypass paths.

In systems with frequent load changes or unstable compressor output, filtration efficiency often degrades not because of contaminant overload, but because the filter structure itself is repeatedly stressed beyond its mechanical tolerance.

Excessive Flow Velocity Undermines Capture Probability

When airflow exceeds design velocity, contaminants behave differently. Particles with sufficient inertia can bypass filtration layers entirely, especially in coalescing filters where capture depends on gradual trajectory deviation rather than direct interception.

High flow velocity also increases turbulence inside the housing, reducing laminar contact between contaminants and filter media. The result is a measurable drop in real-world filtration efficiency despite unchanged filter specifications.

Inlet Contamination Levels Dictate Efficiency Sustainability

Filters are not designed to correct upstream neglect. When inlet air contains excessive particulate matter, oil carryover, or liquid water, even high-performance filter elements will reach saturation quickly.

Once pores are overloaded, filtration efficiency becomes unstable. Some contaminants are captured, others pass through, and pressure differential behavior becomes unpredictable. Efficiency, in this context, is no longer a stable parameter but a fluctuating one.

Installation and Maintenance Practices Decide Whether Efficiency Exists at All

Even with correct filter selection and stable operating conditions, filtration efficiency can collapse due to installation or maintenance errors. These failures are especially dangerous because they are often invisible.

Seal Integrity Determines Whether Air Is Actually Filtered

A precision filter only works if all airflow passes through the filter element. Degraded O-rings, improperly seated cartridges, or uneven flange compression create bypass paths where unfiltered air flows freely.

This “short-circuit airflow” does not reduce pressure drop noticeably, which is why it often goes undetected. However, it renders filtration efficiency effectively meaningless.

Filtration Order Is Not Optional

Compressed air filtration relies on staged separation. Installing fine filters upstream of coarse filters guarantees premature clogging and uneven contaminant loading.

A proper sequence—particulate pre-filtration, coalescing filtration, and high-efficiency polishing—protects each stage and stabilizes overall efficiency. Deviating from this order does not merely reduce filter life; it destabilizes filtration behavior across the system.

Maintenance Timing Influences Efficiency More Than Service Life

Replacing filter elements too late is an obvious problem, but replacing them too early can also compromise efficiency if installation cleanliness is ignored.

Opening filter housings in uncontrolled environments introduces dust, fibers, and moisture directly into the system. Without strict handling procedures, maintenance itself becomes a contamination source, undermining the very efficiency it aims to restore.

Pressure Differential Monitoring Must Be Interpreted Correctly

Pressure drop is an indicator, not a verdict. A stable differential does not guarantee filtration efficiency, and a rising differential does not automatically mean failure.

Experienced operators use pressure data alongside air quality measurements and operating context. Treating differential pressure as the sole decision metric often leads to either premature replacement or delayed intervention—both of which harm filtration efficiency.

Why Filtration Efficiency Is a System Property, Not a Component Feature

The most important insight from real-world compressed air systems is this: precision filter efficiency does not belong to the filter alone. It emerges from the interaction between filter element parameters, operating conditions, and human discipline.

When any one of these three factors is neglected, efficiency becomes temporary, inconsistent, or illusory. When all three are aligned, even conventional filtration solutions can deliver stable, high-purity compressed air over long operating cycles.

Understanding this distinction is what separates reactive maintenance from controlled air quality management—and ultimately determines whether compressed air supports production reliability or quietly undermines it.

Join us

Join us After-sale service

After-sale service News

News