Stainless Steel Compressed Air Filter for Sterilizing-Grade Applications

In industries where compressed air is treated as a critical process medium rather than a utility, the stainless steel compressed air filter plays a decisive role in system reliability, contamination control, and regulatory alignment. When operating pressures reach 1.0 MPa and air purity requirements move into sterilizing-grade territory, filtration decisions shift from general engineering preferences to experience-driven risk management. In this blog post, Wuxi Yuanmei, as high quality custom industrial air filters factory, will share the sterilizing-grade stainless steel compressed air filters under high pressure.

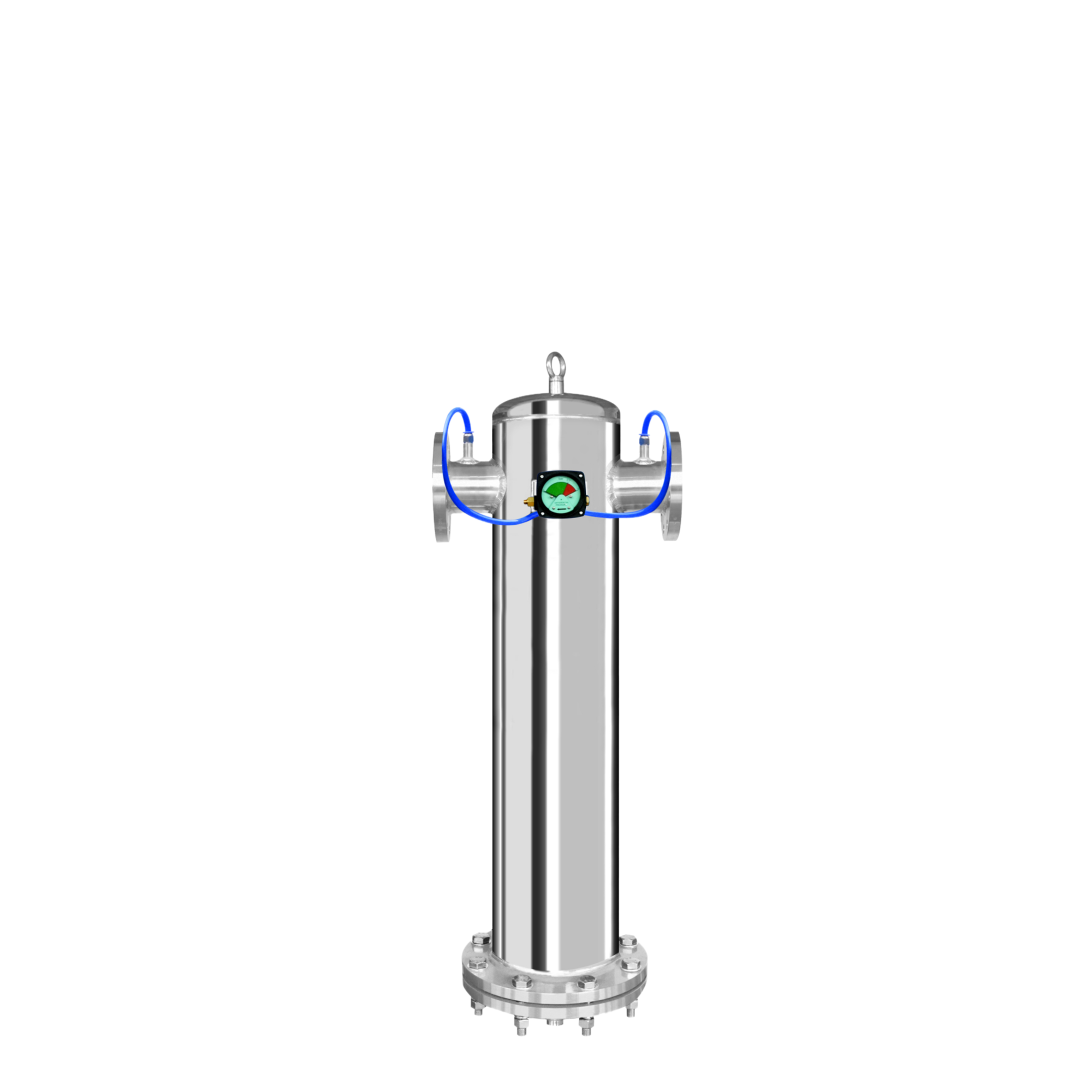

Stainless Steel Compressed Air Filter Design Under 1.0 MPa Operating Conditions

High-pressure compressed air systems expose filtration housings to sustained mechanical stress, pressure cycling, and temperature variation. A stainless steel compressed air filter rated for 1.0 MPa must maintain structural integrity without micro-deformation that could compromise sealing surfaces or internal element positioning.

From experience, stainless steel housings manufactured from SUS304 or SUS316 demonstrate predictable elastic behavior under pressure, minimizing long-term distortion. This is particularly relevant in sterilizing air systems where repeated pressurization and depressurization occur during SIP or purge cycles. Filters that rely on less stable materials often show gradual tolerance drift, leading to leakage risks that are difficult to detect during routine checks.

The pressure rating alone is not the differentiator; it is the consistency of performance over thousands of operating hours that defines suitability in high-demand environments.

Polished Stainless Steel Surfaces and Their Impact on Air Purity

The importance of polished inner and outer surfaces in a stainless steel compressed air filter is often underestimated. An internal surface finish of Ra 0.3 significantly reduces particle adhesion and biofilm formation, especially in humid compressed air streams.

In sterilizing-grade air systems, surface roughness directly affects cleanability. Polished stainless steel allows for more effective steam penetration during sterilization and reduces the likelihood of residue accumulation after condensate exposure. Over time, this contributes to more stable microbiological control without increasing cleaning intensity.

Externally, polished surfaces also support better inspection practices. Visual checks for corrosion, staining, or mechanical damage become more reliable, which is particularly valuable in GMP-regulated environments where equipment condition is part of compliance evaluation.

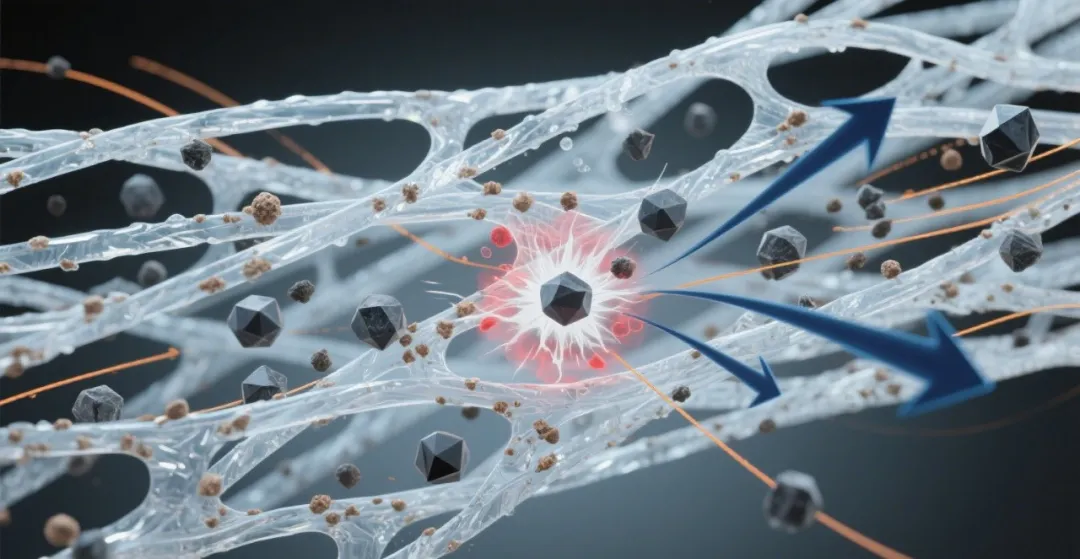

Role of PTFE Sterile Membranes in Stainless Steel Air Filtration

A stainless steel compressed air filter designed for sterilization typically integrates a hydrophobic, folded PTFE membrane as the final filtration barrier. The hydrophobic nature of PTFE prevents moisture penetration while allowing consistent airflow, a balance that is critical in compressed air lines exposed to temperature gradients.

In practice, PTFE membranes maintain filtration efficiency even after repeated sterilization cycles. Their folded structure increases effective surface area, reducing face velocity and helping stabilize differential pressure. This stability is essential for downstream processes that rely on steady air supply characteristics.

Unlike some alternative membrane materials, PTFE demonstrates strong chemical inertness. This reduces the risk of membrane degradation when exposed to trace oils, cleaning agents, or process vapors commonly found in pharmaceutical and food chemical facilities.

Integrity Testing Expectations for Stainless Steel Compressed Air Filters

100% DOP integrity testing has become a baseline requirement for sterilizing-grade stainless steel compressed air filters. From an operational perspective, this testing provides more than a pass/fail result—it establishes confidence in membrane installation quality and housing integrity.

Experienced users recognize that consistent integrity test results over time indicate stable mechanical interfaces within the filter assembly. When test results begin to fluctuate, the root cause is often not the membrane itself, but subtle changes in sealing surfaces or clamp tension.

Designs that support repeatable integrity testing without excessive disassembly reduce maintenance-induced variability. This is an often-overlooked benefit of well-machined stainless steel housings with precise tolerances.

Stainless Steel Compressed Air Filter Compatibility with Sterilization Processes

Sterilizing air systems frequently rely on steam-in-place procedures. Stainless steel compressed air filters with PTFE sterile membranes tolerate high-temperature steam without loss of filtration performance when properly specified.

The key factor is uniform heat distribution. Stainless steel conducts heat evenly, reducing thermal gradients across the filter housing. This helps prevent localized stress points that could otherwise affect membrane seating or gasket compression.

From a system design perspective, filters that can remain in place during sterilization cycles reduce handling risk. Minimizing manual intervention lowers the probability of contamination introduction during reassembly.

Regulatory and Material Compliance in Sensitive Industries

In pharmaceutical, semiconductor, and food chemical industries, stainless steel compressed air filters are scrutinized not only for performance but also for material traceability. The availability of SGS testing documentation for both stainless steel housings and filter materials simplifies qualification processes.

Food and drug grade compliance is not merely a checkbox. It influences how confidently compressed air can be classified within a facility’s quality management system. Stainless steel materials that have passed third-party verification reduce the need for additional risk assessments during audits or system modifications.

Over time, this compliance clarity accelerates approval of process changes involving compressed air, making the filtration system an enabler rather than a bottleneck.

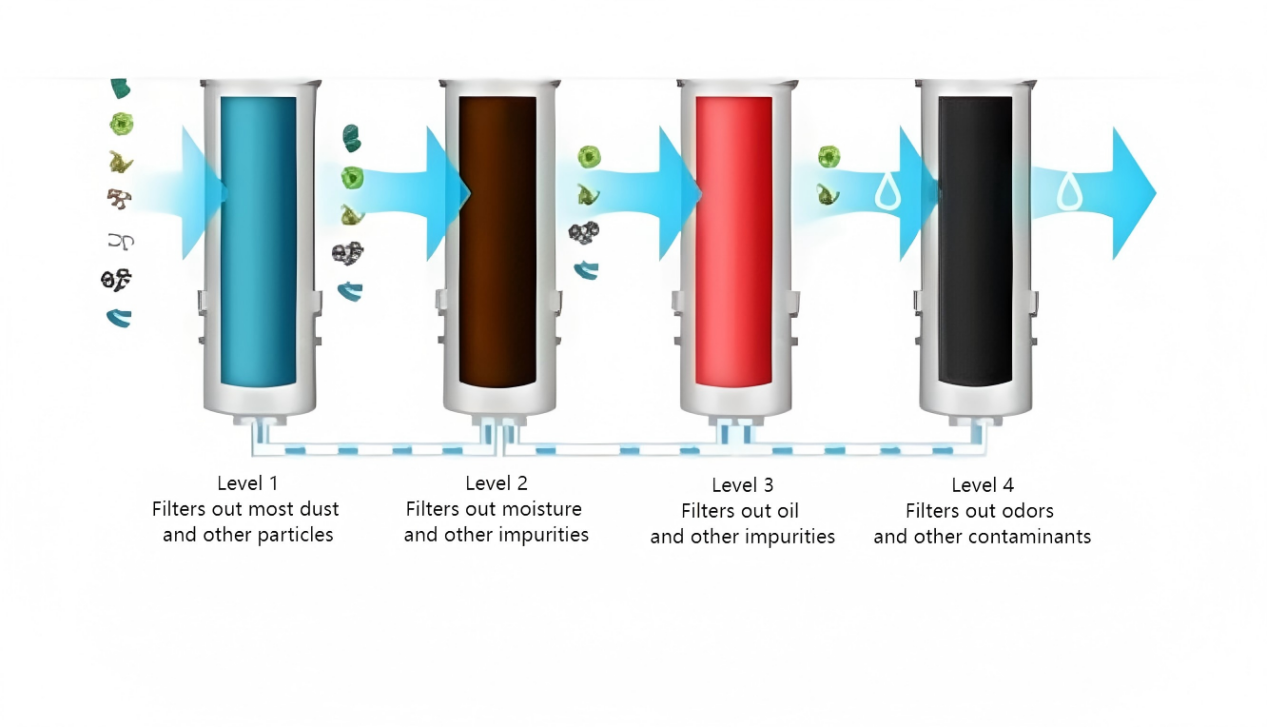

Integration of Stainless Steel Compressed Air Filters in Multi-Stage Air Treatment

Sterilizing-grade stainless steel compressed air filters are typically positioned downstream of dryers and coalescing filters. Their role is not to manage bulk contamination but to act as the final assurance point before air contacts critical processes.

In experience-based system design, maintaining sufficient upstream air quality extends membrane life and stabilizes pressure drop. Stainless steel housings accommodate this role well, as they tolerate upstream fluctuations without compromising downstream cleanliness.

Connection selection—whether sanitary clamps or high-pressure threaded interfaces—should align with maintenance philosophy. Stainless steel filters support both, allowing flexibility across different plant standards.

Maintenance Predictability and Long-Term Operational Stability

One of the most practical advantages of a stainless steel compressed air filter lies in maintenance predictability. Stainless steel threads, clamps, and sealing surfaces retain their geometry over repeated service cycles, reducing the likelihood of progressive leakage.

Filter element replacement becomes a controlled routine rather than a corrective action. This predictability supports data-driven maintenance planning, where replacement intervals are based on performance trends rather than precautionary assumptions.

In facilities where compressed air downtime has cascading effects, this stability contributes directly to operational resilience.

Avoiding Over- or Under-Specification in Sterilizing Air Systems

While stainless steel compressed air filters are robust, misapplication remains a risk. Selecting a housing that exceeds system requirements can introduce unnecessary pressure drop or complicate installation. Conversely, underestimating future sterilization frequency can shorten membrane life.

Experienced engineers evaluate not only current operating conditions but also potential process expansion, increased cleaning cycles, and regulatory tightening. Stainless steel filters offer the flexibility to accommodate these changes when specified with appropriate margins.

The goal is balance: sufficient robustness without sacrificing system efficiency.

Stainless Steel Compressed Air Filters as Long-Term System Assets

When viewed over the full lifecycle of a sterilizing air system, a stainless steel compressed air filter functions as a stabilizing anchor. Its contribution extends beyond filtration efficiency to include mechanical reliability, regulatory confidence, and maintenance consistency.

Rather than focusing on initial performance metrics, experienced users assess how these filters behave after years of exposure to pressure, heat, and cleaning regimes. In environments where compressed air quality directly affects product integrity, this long-term perspective defines value.

A well-specified stainless steel compressed air filter becomes part of the system’s infrastructure—quietly supporting sterile operation, audit readiness, and uninterrupted production without drawing attention to itself.

Join us

Join us After-sale service

After-sale service News

News