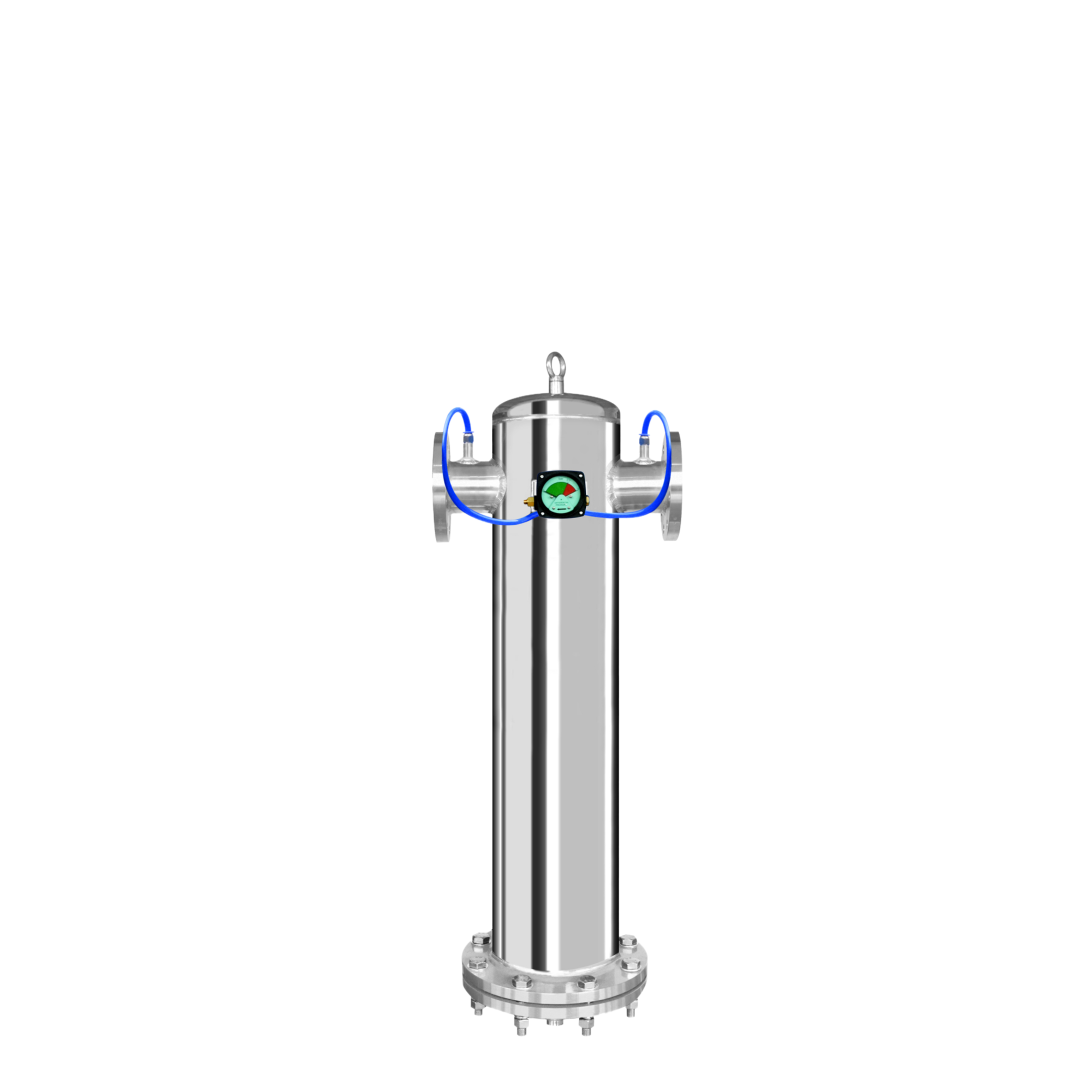

Reliable Filtration with Carbon Steel Flange Compressed Air Filter System

Compressed air systems are vital to industrial operations, powering tools, pneumatic machinery, and production lines. However, without effective filtration, moisture, oil mist, and particulates can compromise efficiency and damage downstream equipment. A carbon steel flange compressed air filter offers a durable and high-performance solution for maintaining air purity in demanding industrial environments. In this blog post, as high performance custom industrial air filters manufacturer, Yuanmei will share the role of carbon steel flange compressed air filter for sale, its advantages, etc.

Role of Carbon Steel Flange Compressed Air Filters in Industry

A carbon steel compressed air filter is specifically designed to remove impurities from compressed air lines, ensuring optimal system performance. These filters are often installed between compressors and pneumatic devices, acting as the final barrier against contaminants that could lead to corrosion or malfunction.

The use of carbon steel flanged housings gives these filters superior mechanical strength and resistance to high pressure. This makes them ideal for industries such as petrochemical, automotive, pharmaceutical, and food processing, where system reliability and air quality are critical.

Structural Advantages of Carbon Steel Flanged Filter Design

The flange connection is one of the defining features of this filter type. Unlike threaded or quick-connect filters, flanged filters can handle higher flow rates and pressures, providing a secure and leak-proof connection.

High Pressure Resistance: Carbon steel body construction allows operation in systems exceeding 16 bar or more.

Ease of Maintenance: Flanged connections facilitate easy assembly and disassembly for filter element replacement or cleaning.

Long Service Life: The robust housing resists fatigue and corrosion, extending maintenance intervals and reducing downtime.

Moreover, the flange design ensures reliable sealing even under fluctuating pressure conditions, maintaining system integrity in continuous industrial use.

Why Carbon Steel Is the Preferred Material for Compressed Air Filters

The choice of carbon steel in compressed air filtration systems is not arbitrary—it provides an optimal balance of strength, cost-efficiency, and durability.

Mechanical Durability: Carbon steel has excellent tensile strength, making it suitable for high-pressure compressed air applications.

Corrosion Resistance: When coated or painted, carbon steel effectively resists oxidation and moisture-induced degradation.

Thermal Stability: It performs reliably in high-temperature environments where other materials might deform.

Cost Efficiency: Compared to stainless steel, carbon steel offers similar strength at a lower material cost.

This combination of performance and economy makes carbon steel a practical choice for industrial compressed air systems where safety and durability are essential.

Filtration Efficiency and Air Quality Control

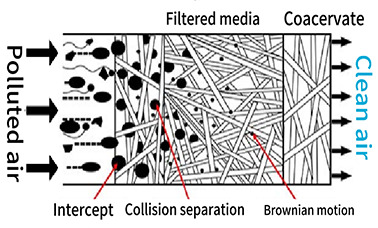

A carbon steel flange compressed air filter typically integrates multi-stage filtration technology. Each stage targets different types of contaminants, ensuring the outgoing air meets strict purity standards.

Pre-filtration: Removes larger solid particles such as rust, scale, and dust.

Coalescing Filtration: Traps oil aerosols and fine moisture droplets through specialized filter media.

Activated Carbon Filtration (optional): Eliminates odor and vapor contaminants, achieving ultra-clean air output.

By combining these filtration layers, the system minimizes wear on pneumatic tools, reduces maintenance costs, and prevents contamination of end products—especially critical in precision manufacturing and food-grade applications.

Application Fields of Carbon Steel Flange Air Filters

The versatility of flanged compressed air filters allows their use across multiple industrial sectors:

Automotive Manufacturing: Ensuring clean compressed air for spray painting, assembly, and tire inflation lines.

Petrochemical Plants: Protecting instruments and pneumatic valves from corrosion and particulate damage.

Pharmaceutical Production: Maintaining sterile, contaminant-free air in cleanroom environments.

Food and Beverage Industry: Removing oil and moisture from compressed air used in packaging and processing.

Power Generation: Preventing contamination in turbine control systems and air-driven tools.

Each of these applications demands reliability, and carbon steel flange filters meet these expectations through their structural integrity and stable performance under heavy loads.

Installation and Maintenance Considerations

To achieve the best results, carbon steel compressed air filters should be installed at key points in the air distribution network: immediately downstream of compressors, before air dryers, or at branch lines feeding sensitive equipment.

Maintenance tips include:

Regular inspection of differential pressure indicators to detect clogging.

Scheduled replacement of filter elements based on operating hours or pressure drop readings.

Checking flange bolts and gaskets to maintain airtight sealing.

Routine maintenance ensures sustained efficiency, prevents pressure loss, and extends the overall service life of both the filter and the pneumatic system.

Sustainability and Energy Efficiency Benefits

Using a carbon steel flange compressed air filter contributes not only to operational reliability but also to environmental and energy efficiency goals. Clean air reduces friction losses, allowing pneumatic tools and actuators to perform optimally at lower power consumption.

Additionally, well-maintained filtration systems minimize waste, oil discharge, and energy loss due to leaks or restricted flow. This results in both lower operational costs and a smaller environmental footprint, aligning with modern industrial sustainability standards.

Conclusion

A carbon steel flange compressed air filter represents the perfect balance of strength, performance, and reliability. Its flanged design ensures high-pressure stability, while its multi-stage filtration guarantees clean, dry, and contaminant-free air for critical industrial applications.

For industries seeking long-term dependability and cost-effective filtration, carbon steel flange air filters are a sound investment. They ensure not only cleaner compressed air but also smoother operations, lower maintenance costs, and extended equipment lifespan—supporting productivity across every stage of industrial processing.

Join us

Join us After-sale service

After-sale service News

News