Precision Compressed Air ACF Filter for Reliable Industrial Filtration

In modern industrial applications, the demand for high-quality compressed air is greater than ever. Contaminants such as dust, oil vapors, and moisture can significantly affect equipment performance, product quality, and overall operational efficiency. A compressed air ACF filter plays a vital role in maintaining clean and dry compressed air systems. By using advanced filter elements, these devices ensure optimal protection of pneumatic equipment and production processes. In this blog post, as a high quality compressed air filter manufacturer, YUANMEI will share the features of precision compressed air ACF filter design, as well as its applications, etc.

Why Choose High-Performance ACF Filter?

An ACF filter is specifically engineered to provide superior air purification in compressed air systems. Unlike standard filters, it offers:

Easy installation with minimal maintenance requirements.

Corrosion-resistant housing that withstands harsh operating environments.

Long service life, reducing replacement frequency.

High mechanical strength, ensuring reliability under pressure.

High-efficiency filtration for critical air applications.

These advantages make the ACF filter the preferred choice for industries such as pharmaceuticals, food processing, electronics, automotive, and precision manufacturing.

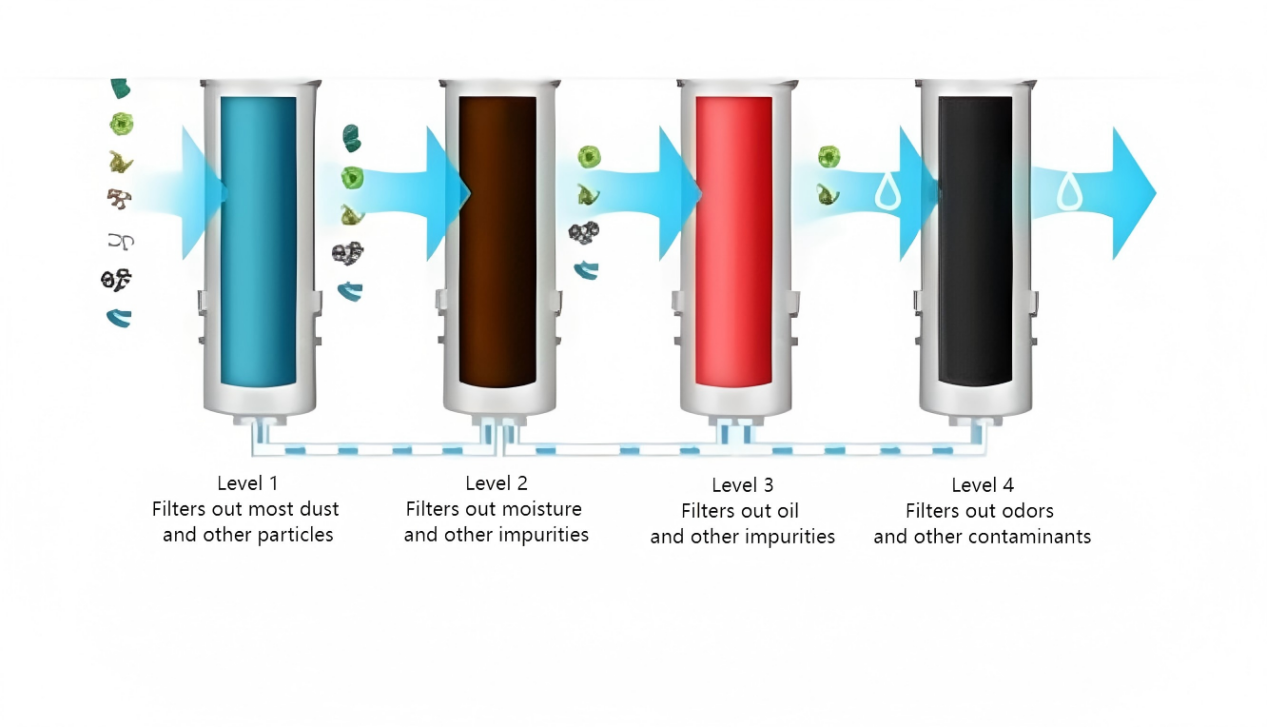

Understanding Filtration Accuracy of ACF Filters

One of the defining features of a precision compressed air filter is its filtration accuracy. The filter element determines the level of particle and oil removal, ensuring compressed air purity. The classification system below highlights the levels of filtration:

Class C (3 Micron – Pre Filter)

Removes coarse particles, rust, and water droplets to protect downstream equipment.Class T (1 Micron – After Filter)

Provides finer filtration to remove smaller solid particles and residual moisture.Class A (0.01 Micron – Line Filter)

Ensures extremely fine particle removal, ideal for sensitive production environments.Class F (0.01 Micron – Fine Filter)

Offers advanced filtration, preventing oil mist and micro-particles from contaminating end products.Class H (0.01 Micron – Activated Carbon Filter)

Specifically designed to remove oil vapors, odors, and hydrocarbons, ensuring clean and odor-free compressed air.

This classification ensures that users can select the right ACF filter element based on specific industry requirements.

ACF Filter Design: Built for Strength and Durability

The construction of the ACF compressed air filter is carefully engineered to handle the challenges of continuous operation:

Corrosion-resistant materials ensure reliable performance even in humid or chemically active environments.

High-strength housings maintain structural integrity under high operating pressures.

Durable seals and joints prevent air leakage, ensuring maximum efficiency.

Precision manufacturing guarantees consistency in filter performance.

The design focus on durability translates into reduced downtime and lower total cost of ownership.

Installation and Maintenance of ACF Filter

One of the key benefits of using a precision ACF filter is the straightforward installation process. The filters are designed for easy integration into existing compressed air systems. Additionally, the modular structure allows quick replacement of filter elements without specialized tools.

Routine maintenance involves:

Regular inspection of filter housings for integrity.

Scheduled replacement of filter elements based on operating conditions.

Monitoring pressure drops to ensure filtration efficiency.

This simplicity in installation and upkeep ensures that operators maintain consistent air quality without incurring excessive maintenance costs.

Applications of Precision Compressed Air ACF Filters

The compressed air ACF filter is widely used across industries where high-purity air is a necessity:

Pharmaceutical manufacturing – prevents contamination of medicines and equipment.

Food and beverage processing – ensures hygienic air supply for packaging and production.

Electronics and semiconductor industries – eliminates micro-particles that could damage delicate circuits.

Automotive and paint shops – prevents defects in surface coating and finishing.

General industrial operations – protects pneumatic tools, valves, and actuators from premature wear.

Each application underscores the importance of selecting the right ACF filter type based on filtration accuracy.

Benefits of Using Precision Compressed Air ACF Filter

By investing in a reliable compressed air ACF filter, industries gain several long-term benefits:

Improved product quality – clean air ensures consistency in production.

Reduced equipment wear – protection from abrasive particles and oil contamination.

Energy efficiency – optimized air purity improves system performance.

Cost savings – longer service life reduces replacement and downtime expenses.

Compliance with standards – ensures air quality meets industry regulations.

These benefits highlight why ACF air filters are essential for sustainable and efficient operations.

Choosing the Right ACF Filter for Your Needs

When selecting an ACF filter, several factors must be considered:

Required filtration class depending on your application.

Operating pressure and flow rate of the compressed air system.

Environmental conditions such as humidity, temperature, and chemical exposure.

Maintenance frequency that aligns with operational schedules.

Working with a reliable supplier ensures that you get the right filter solution tailored to your industry requirements.

Conclusion

The precision compressed air ACF filter is more than just a component; it is a cornerstone of efficiency, reliability, and quality in compressed air systems. With its high-strength design, corrosion-resistant materials, and advanced filtration accuracy, it provides unmatched protection for critical industrial processes.

From Class C pre-filters to Class H activated carbon filters, the range of filtration options ensures that every application has the right level of air purity. By investing in the right ACF filter system, businesses can guarantee long service life, reduced costs, and consistent operational excellence.

Join us

Join us After-sale service

After-sale service News

News