Farewell to Airborne Impurities How Compressed Air Filters Work

Compressed air filters are essential in industrial environments, ensuring that production processes run smoothly while protecting equipment from contamination and wear. The role of a fine compressed air filter goes beyond simple particle removal; it relies on multiple filtration mechanisms working together to provide consistently clean, dry, and oil-free air. Proper filtration reduces maintenance costs, extends equipment life, and ensures process reliability in precision industries. In this blog post, Wuxi Yuanmei, as high performance industrial compressed air filter manufacturer, will share the working principle of precision compressed air filter for sale.

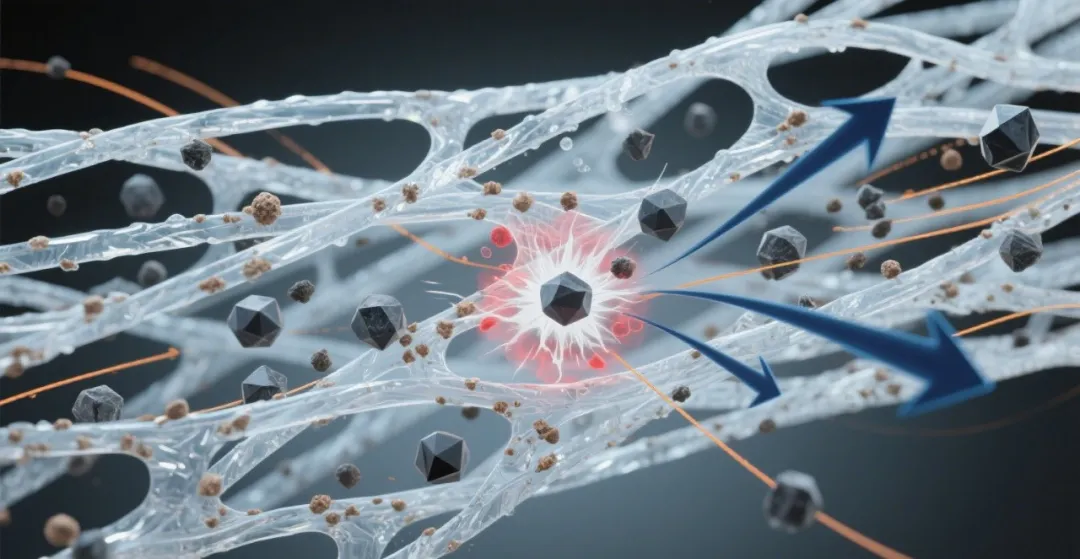

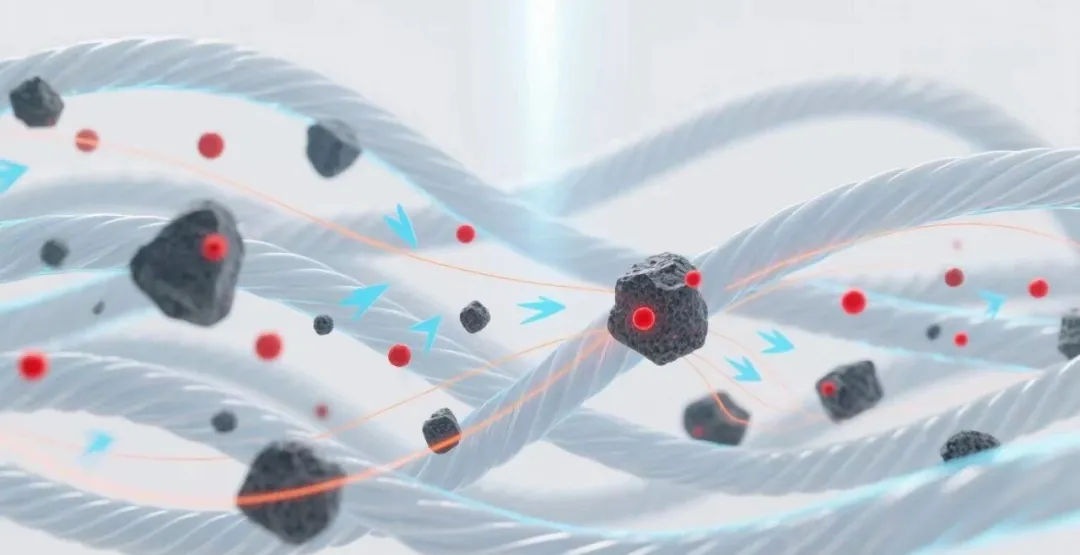

Inertial Impaction

Inertial impaction is the first line of defense in a fine compressed air filter. As high-velocity compressed air flows through the filter media, larger particles and oil droplets cannot follow abrupt changes in airflow direction. These contaminants collide with the fibers and are captured. This mechanism is particularly effective for coarse solid particles and larger oil droplets, preventing them from reaching downstream machinery or sensitive instruments.

Direct Interception

Direct interception targets smaller particles that flow close to the fibers. When the particle diameter is larger than the distance to the fiber surface, it is trapped by direct contact. This mechanism is critical in fine compressed air filters because it captures micro-sized impurities that are too small for inertial impaction to handle. Consistent removal of these particles ensures stable air quality, which is vital for industrial automation and precision manufacturing.

Diffusion and Brownian Motion

Ultra-fine particles, typically in the submicron range, move irregularly due to Brownian motion. This random movement increases the likelihood of contacting filter fibers, allowing these particles to adhere and be removed from the air stream. Diffusion complements the other filtration mechanisms, filling the gap left by inertial impaction and direct interception, and ensures that even the smallest contaminants are eliminated.

Gravitational Settling

Gravitational settling enhances the filtration of heavier particles. As airflow slows within the filter, large contaminants settle naturally under gravity, accumulating in designated areas at the filter base. This passive mechanism works alongside the active mechanisms, improving the overall efficiency of industrial compressed air filters. Gravitational settling is particularly useful for particles that might escape interception due to airflow dynamics.

Electrostatic Attraction

Many modern filter materials generate static charges, or utilize the inherent electrostatic properties of particles. This electrostatic attraction pulls contaminants toward the fiber surface, increasing capture efficiency and further reducing airborne impurities. This mechanism also helps maintain long-term filter performance, extending service intervals and reducing operational costs.

Integrated Filtration for Industrial Applications

By combining these five mechanisms— inertial impaction, direct interception, diffusion, gravitational settling, and electrostatic attraction—industrial compressed air filters can consistently deliver clean air that meets strict purity standards. Reliable filtration is essential for sensitive equipment, including pneumatic controls, instrumentation, spray systems, and automated production lines. High-quality filters prevent product defects, reduce maintenance downtime, and ensure compliance with industrial air quality standards.

Why Choose Wuxi Yuanmei Compressed Air Filters

As a trusted compressed air filter manufacturer, Wuxi Yuanmei designs solutions that integrate these advanced filtration principles. Their fine compressed air filters and industrial compressed air filters provide high removal efficiency for solid particles, oil, and moisture, ensuring operational reliability and extending the life of critical equipment. Whether for high-precision manufacturing, chemical processing, or automated production, Wuxi Yuanmei filters are engineered to deliver stable, contaminant-free compressed air under demanding industrial conditions.

Join us

Join us After-sale service

After-sale service News

News